TPU is a commonly used material for 3D printing flexible parts. TPU combines the properties of both rubber and plastic, making for rubber 3D printing.

3D Printing in the Automotive Industry

Pre-Printing Checklist: How to Ensure Your 3D Model Design Is Ready for Print

RapidMade Masks Help You Face Flying

One of the most anxiety-ridden activities these days is flying. Even if face masks weren’t mandated, most travelers would gladly wear them to enhance their personal safety. In locations where physical distancing is more difficult, people often prefer something more robust than a simple cloth mask.

Our thermoformed, filter-based face masks were enthusiastically worn by one family on a recent flight.

These masks gave us the peace of mind we needed to fly during the COVID pandemic! The masks fit snugly, but are easily breathable. We wouldn’t have flown without the security these masks provided!”

These reusable face masks can be thoroughly sanitized between uses, and the filters can be replaced as needed. If you’d like to order, please click here.

RapidMade Develops Techniques to Strengthen 3D Printed Nylon Parts with Reinforced Fibers

Carbon-fiber-reinforced 3D Printed Nylon Part

RapidMade recently completed research on investigating a solution to produce custom agricultural parts from 3D printed nylon reinforced with fibers in epoxy polymers. The work was completed with Oregon State University and was funded with an SBIR grant from the USDA.

Additive manufacturing reduces the cost and lead time of individually produced parts. Most printed plastic materials lack the strength needed to replace metal parts. Synthetic and natural fiber reinforcement can increase the strength of these lighter plastic parts making them comparable to metal. Well characterized design and manufacturing processes are critical to produce reliable composite parts.

Research focused on:

· structural component designs including materials selection

· pilot manufacturing process development

· manufacturing and mechanical component property validation.

Outcomes identified possible techniques for component design and manufacture to:

· eliminate plastic part anisotropy

· control warp and residual stresses in composite components

· verify plastic/epoxy bond strength

· optimize print orientation

· improve fiber reinforcement application

· establish curing cycle and post-processing requirements.

Future research will study part design techniques to:

· determine best practices

· create structural and processing analysis rules

· explore different material options

· optimize manufacturing processes for small batch production

· evaluate aging and environmentally induced stress responses.

Component design and manufacture showed positive results in terms of low-cost manufacturing process and performance. Fiber-reinforced parts performed better than the plastic-only reference components with strength comparable to the original metal parts. Data suggest that a reliable method for engineering and manufacturing fiber reinforced composites using printed parts was found. Proof-of-concept agricultural and robotic parts that can replace obsolete and custom equipment were shown to be potential affordable alternatives to the originals. Design aspects like matching plastic core and fiber reinforcement characteristics for optimal final composite products need to be addressed in detail.

New composite alternatives can be used to:

· make replacement parts

· increase field productivity

· upgrade or reconfigure machinery

· improve equipment operations and efficiencies

· manufacture components using more sustainable materials

· enable local farms to be more independent in part procurement.

This manufacturing process can enable small production plants to make parts locally as needed. Future work should build on current results by studying custom design, materials selection, manufacturing process optimization and aging and environmentally induced stress responses. Specifically, research focused on bonding reliability between printed parts and fiber reinforcement and combining components in a simple, efficient composite manufacturing process.

Work was subdivided into the following areas:

Mechanical Properties and Anisotropy of 3D Printed Parts. Baseline tests measured printed part mechanical properties prior to testing composite fiber components. ASTM standard tests of mechanical properties and microscopic analysis across a range of printers identified part anisotropy. Print parameters were established to limit anisotropy. Additional design parameters must be developed to limit impact on composite part performance.

Characterization of the 3D Printed Plastic-Fiber Reinforcement Epoxy Bond. Detailed bond tests were performed on parts made using two different fabrication techniques and three alternate fibers. Single lap joints were shear tested to failure to study nylon composite bond response. Multiple test scenarios characterized the nature of the bond, the minimum overlap requirements and the relative results with different fiber materials. Part failure occurred before the bond confirming the hypothesis. Actual bond strength data was captured. The use of organic fibers as an alternative lower cost composite reinforcement was confirmed.

Composite Manufacturing Process Evaluation. An established composite manufacturing process employed for small batch production was used for testing. Research focused on adapting these techniques to printed materials. Successful composite test parts were created and used for mechanical properties testing. Elements of the composite manufacturing process were investigated to improve the epoxy-nylon bond and to minimize component stress during heat curing. Trials were conducted to further simplify manufacturing techniques and optimize part quality. Work focused on three test components and three alternate fiber reinforcement materials. Iterations evaluated manufacturing process and part quality improvements. Findings were summarized in the published research.

Warping of Components During Curing. The effects of bonding between thin wall printed parts and fiber reinforcement using different configurations was studied. Thin wall components and the ability to assemble larger composite parts from multiple smaller printed parts are critical requirements for farming applications. The work focused on composite cooling times and fiber direction. Non-traditional inverse core sandwich constructions were also studied and tested. Results were positive; additional work will focus on further internal part stress reduction.

Design of Fiber-reinforced Test Components: Three designs were tested: a tractor linkage arm, a compound moment arm and a robotic fruit picker. These parts were selected as they experience different operational compressive and tensile stresses. The fiber reinforced parts were dimensionally comparable to the original metal parts. Mass reduction and low-cost manufacturing were assessed.

Construction and Testing of fiber-reinforced, 3D printed composite parts: Baseline finite element analysis for loading and elastic deformation simulations was performed on part designs. Unreinforced printed parts were mechanically loaded and tested; experimental results were compared to the simulations and test part baselines were created. Loading tests were repeated using fiber reinforced composite parts to characterize mechanical property augmentation due to fiber-reinforcement and the overall part performance. Extensive testing was conducted on all three parts using a range of fiber materials. The results were cataloged and contrasted to establish performance models. The work also analyzed the impact of composite construction methods on finished part mechanical properties.

Impact of temperature cycling on fiber-reinforced, 3D printed composite parts: Cyclical temperature tests performed on all parts using multiple fiber materials determined fiber bonding impact. This work measured bonded composite delamination using non-destructive test methods. Results confirmed that printed part design and fiber reinforcement location can impact composite bonding in response to thermal stress. Minimum printed part thickness must be determined to minimize warping, during the initial curing process and in response to subsequent thermal stress. Printed parts need to be designed and manufactured to account for internal thermal stress factors. Design techniques to improve part structural strength properties need to be included in future work. Finally, reinforcing composites should be selected to have a coefficient of thermal expansion that matches the printed core to minimize thermal stress warping.

To read the complete technical research report go to https://www.rapidmade.com/resources

RapidMade Presents at NW Electronics Design & Manufacturing Expo

Alex Nolan, RapidMade Sales, explains Additive Manufacturing options to NEDME participants

Mark Eaton, RapidMade’s VP of Sales and Marketing presented at the NW Electronics Design & Manufacturing Expo where he spoke about 3D Printing technologies and Additive Manufacturing’s evolution into final part production as a solution to short-run, custom manufacturing.

Recognizing that 3D printing is a means to an end, RapidMade’s team works to understand customers’ priorities to determine whether Additive Manufacturing is appropriate, and if so, which technology is the best fit. Regardless of the technology employed, additive manufacturing is redefining the ways in which things are made. We’re moving from mass, overseas production which requires extensive inventories to mass, localized customization which involves managing electronic files. Advances in materials allow a transition from metal to plastic finished parts. And with the introduction of HP’s Jet Fusion printer, the process dramatically reduces lead times and costs.

Contact us to learn more.

RapidMade's Manufacturing Team Expands with Summer Heat

RapidMade has expanded its manufacturing staff this summer. Please join us in welcoming:

Drew Christensen

All the way from the distant land of Wisconsin is our new Shop Technician, Drew Christensen. He's been a mold maker, fab tech, model maker, and everything in between. You can find Drew kayaking, fishing, or camping when he's not doing side woodworking projects. His ideal job would be what he's doing now, working with his hands. We're happy to have Drew join the team.

Max Poroj

Max Poroj, a specialist in CNC programming, machining, and manual programming, is our new Mill & Machining Operator. When he's not taking wrestling with his 5 kids, he loves to go camping with them to enjoy the outdoors. He's a big fan of dark science fiction, 3D modeling, and listening to audio books and podcasts in his free time. Welcome to RapidMade, Max!

Cameron York

Our newest 3D Print Tech, Cameron York, is an Oregon-native packaging manager and 3D modeler. He spends his off hours playing Frisbee golf, camping, and skateboarding. His dream job would be to own a 3D modeling studio. We're excited to see what you can create, Cameron!

Ryan Colindres

Ryan was recently promoted to the position of Shop Supervisor. He grew up cage-free, Oregon-raised in Eugene and is an Industrial Designer. When he's not running the shop, he's creating, modeling, and designing; he craves adventures. You can find Ryan biking, swimming, hiking, and "camping, baby". Ryan hopes some day to be a serial entrepreneur. Congratulions, Ryan!

Dragons Return to Merry Ole England, Thanks to 3D Printing

Photo Credit: 3D Systems

A favorite perk of living in England was access to some of the greatest landmarks on earth. One such treasure was a mere 20-minute train ride away. Kew Gardens in Richmond is home to the Great Pagoda

“commissioned in 1761 during the reign of King George III... the striking 163-foot structure with its ornate and highly fashionable Chinoiserie style”

Atop its magnificent roof once stood 80 fierce wooden dragons that were removed, but not forgotten, in a 1761 renovation. Now they are being lovingly recreated by the magic of 3D scanning, reverse engineering and 3D printing - hopefully before our next "trip across the pond."

3D Printed Periscope Phone Case Allows Everyone to be a Photo Pro

Defox has launched its Periscope Case, a novel phone case that uses mirrors and straps to transform one's smartphone into a versatile, easy-to-use camera that enables active photography. Manufactured in Portland, Oregon, Defox is using RapidMade's new HP Jet Fusion 3D printer to produce the cases in sturdy nylon. Act now for the early bird discount!

3D Printing Advocate Shares "The Practice of Innovation"

Jan Baum to discuss Additive Manufacturing at Stevenson University's Dell Lecture (photo credit: What Weekly)

I worked and lived in Maryland just as 3D printing was gaining public acclaim. There was a vibrant and supportive Additive Manufacturing community, centered in Baltimore, most often led by Jan Baum. An early adopter and advocate, Jan recognized the power of 3D printing to transform manufacturing, and she promoted its adoption as a way for Maryland to solidify its position as a premier manufacturing base that would allow it to offer high-skilled workers a secure income.

I'm pleased to see that Jan, the founder and director of Object Lab and a professor at Towson University, is still actively spreading this important message. Jan is one of the first (and most engaging) professionals I met during my tenure in Maryland. I loved that she was a female role model in a traditionally male field.

She'll be discussing "The Practice of Innovation" at the SOLVE Center on March 21 at 5 PM.

NAS Pax River Event Features Mobile 3D Printing to Promote STEAM

NAWCAD's FabLab will be open to visitors at Technology and Arts Expo (DCmilitary.com - photo credit)

We were living in Maryland just when interest in 3D printing was being fueled by technological breakthroughs and extensive media hype. A consortium of additive manufacturing advocates there preached its potential to accelerate business development if educators insured a ready and willing workforce. One locale heeding its message is Southern Maryland, home to the Naval Air Station (NAS) Patuxent River. To promote interest in STEM, NAS Pax River volunteers will host an event this Saturday at the Technology and Arts Expo at the Patuxent River Naval Air Museum.

A featured attraction will be NAWCAD's FabLab:

“a place where makers can take their ideas from concept to prototype for projects involving rapid prototyping, accelerated modeling and collaborative learning opportunities.”

The FabLab houses 3D printers, CNC mills and laser cutters and other prototyping equipment.

This region, nestled between the Potomac and Patuxent, is often better known for its access to the Chesapeake Bay than advanced technology - despite the expansive naval base. Hopefully these enthusiastic advocates will change that perception - almost makes me miss Maryland.

HP Jet Fusion Delivers Injection Mold Quality without the Mold

3D printed part

Mold no more! For small and medium-batch production runs, slash cut part cost and accelerate delivery speed with HP Jet Fusion:

- No tooling costs

- Limitless iterations

- Design freedom

- Lower engineering costs

- Collapsed delivery timelines

- Production-quality parts

Contact us for a quote.

HP Announces New 3D Printing Materials for 4200 Jet Fusion Series

RapidMade's HP Jet Fusion in action

RapidMade is pleased to share that HP is expanding material options for its Jet Fusion 3D printer. Recognizing that material selection, performance, quality and cost have been barriers to additive manufacturing adoption, HP has focused aggressively on product development and accessibility.

Now, in addition to its 3D High Reusability PA 12, HP plans to offer:

- 3D High Reusability PA 12 Glass Beads - designed to produce "stiff, low-cost, quality parts"

- 3D High Reusability PA 11 - formulated to create "ductile, quality parts" at an unbeatable price

A key to its speed-to-market success has been HP's decision to encourage an Open Platform where key suppliers collaborate to accelerate material innovation.

RapidMade looks forward to including these revolutionary nylon powders in its operations.

RapidMade Brings Goodnuss to Founder and Other Entrepreneurs

One of the most enjoyable aspects of working with entrepreneurs is seeing them – and their projects – come to fruition, orin Lizz Hampton’s case – to nutrition! Lizz is one of our favorite success stories, especially given that she is among RapidMade’s first customers, dating back to its first year in business.

Lizz came to us with a product idea that would make it easier for people to make fresh nut milk at home. The product concept itself was very simple, however the design requirements were very complex.

Over the course of the past 4 years, we have worked with Lizz to simplify this revolutionary product through hundreds of prototype iterations, helping her streamline from more than 15 complex parts down to 4 simple parts and then supporting her pivot away from a device into a reusable, mess-free nut milk bag.

“I wouldn’t have been able to get this far without Micah and his team at RapidMade. Not only did they help me develop a better product, they provided essential insight into how it would need to be manufactured, important engineering considerations and top quality parts for my prototypes. Above all else, they have been there to support me on my journey and believe in the product I am creating, which is invaluable to me as a young maker/designer. ”

As of October 17th, Lizz’s reusable, mess-free nut milk bag is available for pre-order on Indiegogo. We are helping her spread the word about her launch because we believe in supporting our customers and doing our part to help them succeed. If you are interested in supporting Lizz and helping her get her product manufactured, please click this link

You can also check out her website, which is full of funny videos.

If you are not a nut milk drinker, we’re sure you know someone who is and would love this product! If you are not able to support her campaign financially, please share with your network so she can build her dream company.

At RapidMade, we believe in helping our customers achieve their goals, whether it’s developing or producing a product for commercial use, creating a prototype for an entrepreneurial project or making displays for retail spaces, we are dedicated to helping our customers succeed with superior products.

Now You Can Scratch That Itch Using a 3D Printed Cast

My traditional cast for my broken right wrist

I am now 3 weeks into my cast-restricted convalescence. And yes, it is as annoying, smelly and uncomfortable as everyone says. So when my accident occurred (a large dog was desperate to greet Luke and I was in its way), I toyed with getting our team to scan and 3D print a cast. The doctors were not keen, and since traditional casts are reliable, cheap and quick, I didn't argue.

If I had gone that route, what would have been involved? Well, as in the traditional approach, we would have waited a week for the swelling to go down. Then I would have had a 3D scan to get an exact image of my arm. The resulting file would then be modified to 3D print the lattice-like open "exo-skeleton" cast which would snap into place. Oh, to be able to scratch and shower undeterred! But I'm under no illusions; it could have been a pricey and time-consuming project - the design would have to withstand use and be printed in a non-toxic material, so while I was in a traditional cast 1 week after my fracture, it would likely have taken longer for a high-tech alternative.

But there are times when I'd give almost anything to scratch that itch.

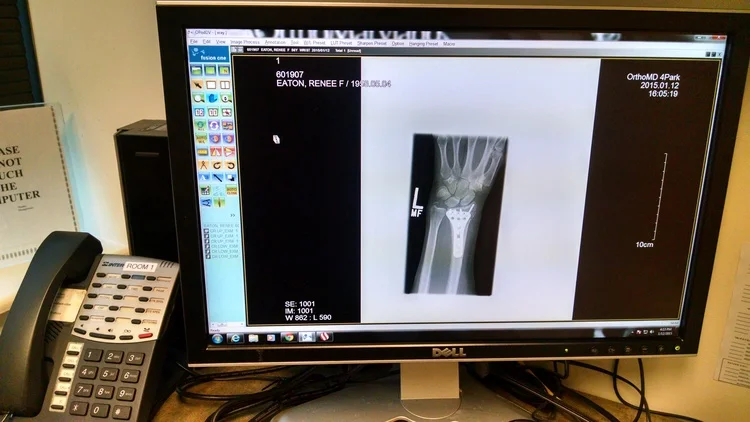

Research Study Demonstrates Benefits of 3D Printing in Surgical Outcomes

Study confirms value of 3D printed models in planning wrist surgeries

If you read our blog, you know that we are especially interested in the medical applications of 3D printing. I've written a few times about its adoption in surgery planning. Now a recent published study conducted by Italian surgeon Dr. Nicola Bizzoto quantifies three advantages of 3D printing a patient's wrist (distal radius) fracture before operating.

Having an exact replica of the broken bones allows the physician to thoroughly plan the surgery in advance, knowing where to place screws and which plate size to implant. This preparation reduces operating room and anesthesia times. Shorter surgeries save hospitals money and less anesthesia improves patient outcomes. The model can also be used to improve patient education.

I only wish this practice had become widespread before my wrist surgery in 2014. The operation took longer than planned because my wrist was worse than expected - there were bone fragments that had to be removed. As a result, the anesthesiologist had to fully sedate me, and I ended up spending New Year's Eve in the hospital - not a Happy start to 2015, so while I hope to never go through a similar procedure again, I'm heartened by the increased popularity of 3D printing in medicine.

3D Printing Battles Animal Extinction

Ivory-look-alike artwork (Image Credit: 3ders.org)

3D printing enthusiasts are using additive manufacturing to combat animal extinction on multiple fronts. One Italian-based artist, Andrea Pacciani, is creating exotic ivory-alternative objects that she hopes will entice patrons toward her "sustainable, animal-friendly pieces." Not only do the items look and feel like ivory, because they are 3D printed, Pacciani is able to create designs that cannot easily be produced with traditional carving methods.

The International Fund for Animal Welfare (IFAW) has also adopted the technology to create a graphic reminder that we won't be able to just 3D print more animal species if they are driven to extinction. Its ad campaign, produced by Young and Rubicam, shows partially printed, like-like reproductions of an elephant, orangutan, and whale to communicate its dire message.

Other nonprofit firms, such as Paso Pacifico have used 3D printing creatively to advance their causes. Paso Pacifico chose

“to create 3D printed decoy sea turtle eggs to track and take down poaching rings, and scientists at the International Centre for Birds of Prey (ICBP) have 3D printed vulture eggs embedded with micro-sensors to learn vital information about vulture nesting habits.”

These initiatives show the commitment and ingenuity dedicated to saving at-risk species and the potential and versatility of 3D printing.

"Armed" with 3D Printing, MIT Scientists Build Hydraulic Robots

Credit: Newscientist.com

MIT researchers recently turned to 3D printing in order to build a mobile robot. Leveraging one advantage of 3D printing, the robot’s body was printed in one piece capable of movement using hydraulics. Both in universities and at home, roboticists are looking more to 3D printing to build unique parts, rapid prototypes, and even robotic prostheses. Though the relationship between the two industries is just beginning to gain momentum, there are already myriad ways in which 3D printing has opened up possibilities for makers and businesses in the field of robotics.