3D Printing in the Medical Industry

The medical industry―with its need for customizable, biocompatible and sterilizable plastic and metal components―is one of the most promising fields for 3D printing applications. It may sound like science fiction, but many types of medicine are already benefiting from additive manufacturing, with more applications being developed year after year.

Every day, 3D printing provides patients with affordable custom prostheses, implants, and devices; it enables doctors to perform their jobs more effectively with custom tools and models; and it helps medical device companies develop better products, faster. Some researchers are even working on technologies to 3D print living tissue and organs!

Keep reading to learn why 3D printing is such an effective tool for the medical industry and some of the ways it is helping medical professionals provide better care at less cost. For a general overview of 3D printing, check out our Complete 3D Printing Guide.

Advantages of Medical 3D Printing

So what makes 3D printing—also known as additive manufacturing—so useful in the medical industry? In many ways, the needs of modern medicine align perfectly with the capabilities of 3D printing.

Implants, prostheses, devices, anatomical models, and even some tools need to be designed for each patient. With traditional technologies, this customization is extremely expensive and time-consuming. 3D printing, on the other hand, can produce small runs of custom parts―even just one part at a time―at no extra cost and without any setup time or tooling. Additive manufacturing excels at highly customized applications, and the human body is about as custom as it gets!

However, it doesn’t stop there. Medical devices often require complex designs, internal geometries or organic forms. For example, think about the curves and hollow spaces in a hearing aid―or a heart! And did you know that implants are more likely to be accepted by a patient’s body if they have porous surfaces? These types of shapes are difficult or even impossible to make with traditional manufacturing.

3D printing can easily produce complex geometries in plastic or metal―all in one piece and with a high level of accuracy. This can allow for improved designs as well as reduced costs and production times. Eliminating crevices and gaps between multiple parts has the added benefit of making devices easier to sterilize and harder for bacteria to grow on.

When it comes to medical devices, the materials used in a device are at least as important as the design of the device itself. 3D printing is compatible with biocompatible and sterilizable plastics and metals that offer a range of mechanical, chemical and thermal properties. 3D printed components can be rigid or flexible, hard or soft, and smooth or textured. Whatever the demands of an application, 3D printed materials can meet them.

There’s also the unmatched production speed of 3D printing when compared to other technologies. Nowhere is this more important than when it comes to treating patients. The long timelines of traditional manufacturing often mean that patients are left waiting to begin their treatment program or have to go through multiple intrusive doctor visits over a long period of time to fit and re-fit medical devices. At best, this causes the patient inconvenience and additional discomfort. At worst, these delays can cause patients’ conditions to become more serious or even fatal.

Finally, 3D printers allow medical professionals to say goodbye to plaster casts by using 3D scanning and x-rays to quickly create detailed 3D models, eliminating the need to store countless physical casts for ongoing patient care. This does more than just save space—plaster casts can degrade over time or through mishandling. 3D images provide accurate, permanent models that can be accessed anywhere, saving medical professionals time and expense.

For more information on the unique design capabilities of 3D printing, take a look at our Design for Additive Manufacturing (DfAM) Guide.

Medical Applications for 3D Printing

3D Printed Prosthetics

The intense customization involved in prosthetic medicine makes prostheses famously expensive and time consuming to produce. This is largely due to the importance of getting a perfect fit to create a functional and comfortable prosthesis for the patient, as the devices and their sockets are subjected to rigorous use. For these reasons and more, 3D printed prostheses are revolutionizing the industry.

The prosthesis-fitting process typically consists of multiple castings and follow-up appointments to fine tune the fit. For patients, this is often more than just an inconvenience: having a cast made is uncomfortable, and the many fitting visits can be invasive to patients who may be sensitive about their condition. Not to mention, all of the time spent fitting and re-fitting is time spent without a properly fitted prosthesis.

With 3D printing, patients don’t even need to sit for a physical cast. Instead, technicians can use a 3D scanner to quickly create a precise 3D model of the patient’s residual limb. This 3D scan then serves as the basis for an accurate and affordable 3D printed socket that typically only requires a single fitting visit.

Patient-Specific Devices and Implants

Prosthetic medicine is not the only medical field that requires a high degree of customization. Patient-specific devices (like hearing aids) and implants (like artificial joints, cranial plates and even heart valves) are rapidly converting to 3D printing for its easy customization and fast production.

Heart valves and hearing aids have traditionally required a full week of extensive, handmade adjustments by skilled workers. Prior to 3D printing, producing a hearing aid took nine steps from casting to fitting. Now, hearing aids can be 3D scanned and printed in a single day.

There are design advantages, too: 3D printed silicone heart valves provide an exact fit that rigid, traditionally manufactured heart valves simply can’t. For implants like titanium artificial joints or cranial plates, 3D printing can create complex, porous surfaces that make patients’ bodies less likely to reject the implants.

Dentistry and Orthodontics

Like prostheses, dental implants and orthodontic devices require extensive customization with a high degree of accuracy. We rely on our teeth to stand up to heavy use day after day—as a result, dentures, crowns, implants and retainers need to be durable, precise and comfortable. On top of that, they need to be made of biocompatible materials like cobalt chrome and porcelain.

3D printing allows dental and orthodontic professionals to accomplish all of this faster and at less cost than traditional methods like machining. A combination of 3D scans and x-rays can be used to produce high-quality dental devices without any casting or setup time.

Even for devices like braces or expanders that do not require 3D printed components, 3D printed models made from sterilizable plastics can be used to measure form and fit, eliminating the need for lengthy patient fittings or multiple visits.

Medical Device Development

Research, development and certification for medical devices is extremely resource-intensive and time-consuming. Often, the high price of medical devices is due not to manufacturing costs but expensive product development. Because 3D printing offers a range of biocompatible and sterilizable materials, it helps medical device developers produce and test functional prototypes in a fraction of the time, leading to more iterations, better products and less expensive care.

Additive manufacturing shines in product development because of its fast turnaround, easy alterations and low cost for very small volumes of parts—it can easily save businesses hundreds of thousands of dollars and months of time in product development. Given the rigorous and lengthy certification process required for medical devices, these time and cost savings are especially valuable.

Personalized Surgical Instruments

In the operating room, precision and efficiency are everything. The unique challenges of each procedure cannot be understated—every patient’s body is different, as are every surgeon’s hands. When fine control is at a premium, why should surgeons be limited to one-size-fits-all surgical tools?

3D printing provides an affordable and timely method for producing personalized surgical tools that are tailored to the needs of each surgeon and each procedure. Made with sterilizable and biocompatible plastics and metals, these tools can be single-use or reusable. And because these tools can be produced in such a short time, hospitals don’t need to keep a large back stock of instruments and can instead order production as needed.

Surgical instruments that are personalized to the size and shape of each surgeon’s hands—plus additional customization for each application—can dramatically improve outcomes and efficiency. Moreover, surgical guides made specifically for each patient can increase accuracy while reducing the amount of time in the operating room by eliminating the need to consult diagrams and assistants.

Custom Anatomical Models

High-quality anatomical models are expensive, and even the best offer a finite range of options. Students and professionals alike regularly use models for education, training, surgery preparation and to provide visual aids for patients.

With 3D printing, medical professionals and educators can create affordable custom anatomical models for a range of purposes. For example, surgeons can practice for difficult surgeries using patient-specific models that precisely reproduce the conditions that they will encounter during surgeries.

Bioprinting

What if 3D printers could use cells and organic matter instead of plastic and metal? That’s the basic concept of bioprinting—the cutting edge of 3D printing in the medical industry.

Although most bioprinting technologies and applications are still in early development, researchers have had success printing bones, skin, and cartilage. One day, we may even be able to 3D print functioning organs.

Bioprinting works like other 3D printing technologies: using a range of methods, material is deposited or solidified in successive layers to build 3D objects. With bioprinting, however, printers use stem cells or cells cultivated from tissue samples. These cells are held together with a binding gel or collagen scaffold.

Bioprinted body parts and organs would allow patients’ natural tissue to grow over the 3D printed parts and eventually replace the cells with their own. And while we likely won’t be seeing functioning bioprinted organs anytime soon, the technology is already helping researchers carry out research on living tissues without having to acquire them from a living organism.

Medical-Grade 3D Printed Materials

When it comes to medical products, not all materials are created equal. Medical devices and implants need to be sterilizable, as the presence of microorganisms can lead to life-threatening infections. And any product that will be in contact with tissue must be biocompatible—meaning that it is not toxic to living tissue and will not produce harmful reactions if placed in a biological system. Implants in particular must be made of materials that are likely to be accepted by recipients’ bodies. Corrosion-resistance is equally as important, as our bodies’ fluids are surprisingly corrosive over time. And because implants need to stand up to heavy long-term use, these materials must be strong, durable and lightweight.

Fortunately, modern 3D printers are compatible with a number of plastics and metals that meet these qualifications. Below, we’ve outlined a few of the most commonly used 3D printed materials for the medical industry.

Nylon PA-12

This general-purpose plastic is lightweight, durable, corrosion-resistant and able to be sterilized with a steam autoclave. Nylon PA-12 offers good flexibility and chemical resistance. It is also among the fastest and most affordable medical-grade materials to print and is compatible with Multi Jet Fusion printing and SLS. Nylon PA-12 is USP Class I-VI and ISO 10993 certified. Read more about nylon PA-12.

PC-ISO

PC-ISO is a biocompatible polycarbonate (PC) engineering thermoplastic used in FDM 3D printing. It has a lower-quality finish than Nylon PA-12 but is commonly used for surgical guides, prototypes and molds. PC-ISO can be gamma or EtO sterilized and is USP Class I-VI and ISO 10993 certified. Read more about PC-ISO.

Titanium

Titanium is the king of biocompatible metals and is the most popular material for medical implants. Replacement joints, pacemakers, cranial plates, dental implants and more are all regularly made from titanium. Titanium is extremely strong, lightweight, corrosion-resistant and non-reactive. It can be 3D printed using DMLS, one of the most expensive 3D printing technologies. Read more about titanium.

Cobalt Chrome

Like titanium, cobalt chrome has very high corrosion resistance and excellent biocompatibility. It offers additional strength and hardness over titanium and is commonly used for replacement teeth in addition to heavy-use replacement joints like knees, hips and shoulders. Cobalt chrome is also 3D printed using DMLS. Read more about cobalt chrome.

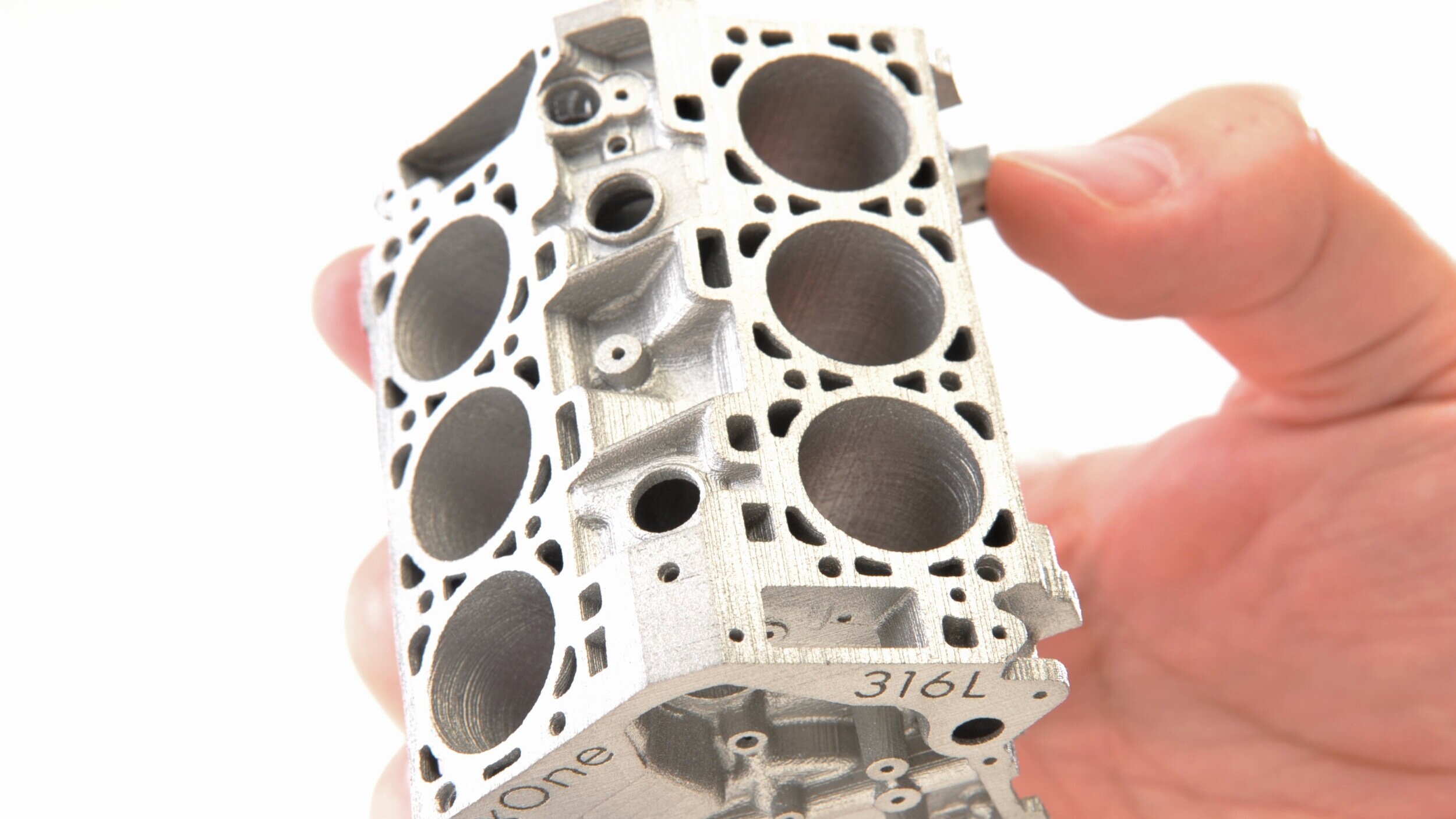

Stainless Steel

Stainless steel is strong, sterilizable and biocompatible; however, it does not offer the same long-term corrosion resistance as titanium or cobalt chrome. As a result, stainless steel is more commonly used for surgical tools and temporary implants like bone screws. Stainless steel parts can be 3D printed at a much lower cost than other metals with direct material printing. Different types of stainless steel offer varying levels of strength, rigidity and chemical resistance. Read more about stainless steel.

Silicone

Silicone is a flexible rubber material with a wide range of applications in the medical and food industries. It is heat-resistant and can be Class V or Class IV certified for biocompatibility. Silicone can be approved for both short- and long-term implants. Catheters, respiratory masks, medical tubing, and seals are all regularly made from silicone.

While silicone 3D printers are still in early development, silicone casting with 3D printed molds is a fast and affordable way to manufacture high-quality parts and products. Read more about silicone.

The Future of 3D Printing in Medicine

Given the unique needs of every patient and body, medical devices often require the most customization of any type of product in any industry. But, because of the high costs and long lead times of tooling for traditional manufacturing, these devices have historically been expensive and slow to produce. 3D printing—with its unmatched ability to produce small runs of highly customized parts—is redefining what is possible in medicine.

Tailoring medical solutions to patients and doctors improves outcomes; reducing costs and production times increases accessibility. Now, custom medical devices, implants and tools are more accessible than ever. As 3D printing technologies continue to develop, healthcare providers and researchers will continue to explore new applications—from implants and surgical tools to tissues and functioning organs.