3D Printed Materials

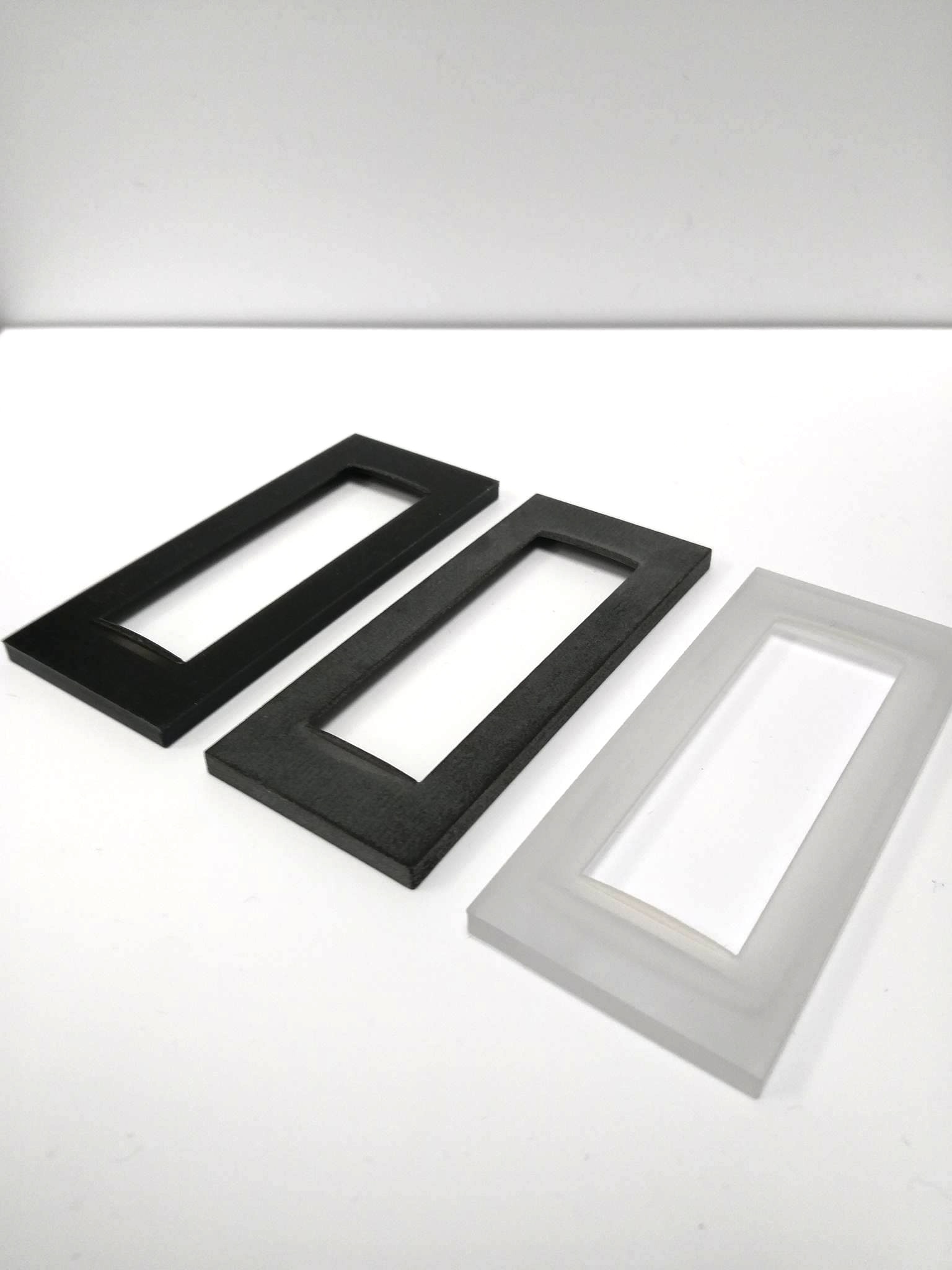

Selecting the right material for your needs is one of the most important part of any project. In fact, we recommend picking a material first, since it will determine what technologies you can use.

The industrial thermoplastics and metal alloys below offer a wide range of properties to suit any project. Click on any material to learn more about it and get full specifications.

Looking for more information? Learn more about 3D Printing for Prototyping.

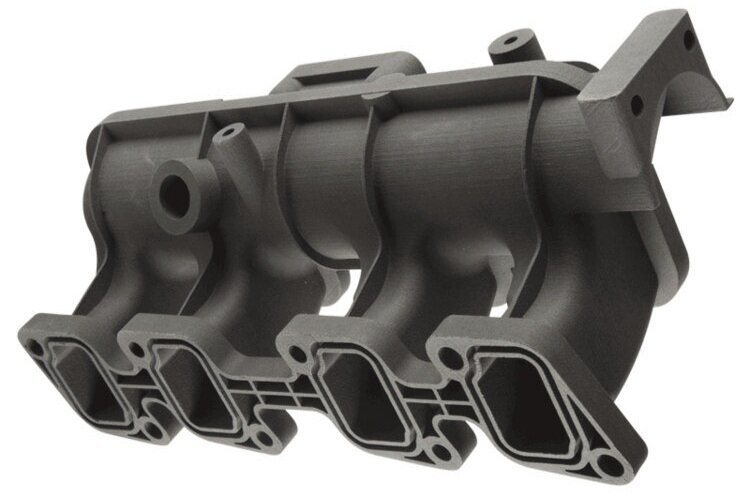

Nylon PA-12

The best printed plastic on the market for most applications. Durable, lightweight, inexpensive and quick to produce. Good chemical and heat resistance. Superior surface finish makes it an excellent option for industrial parts, functional prototypes and consumer products alike.

ABS

Fused Deposition Modeling (FDM)

Tried-and-true plastic for accurate parts and functional prototypes. Good alternative to nylon PA-12 for slightly larger single-piece parts; however, we generally recommend nylon PA-12 when possible due to its lower cost, improved finish and faster print time.

PMMA

The largest 3D printing available, great for producing molds and tooling. A fast and inexpensive alternative to large machined parts, especially in small to medium runs. The Voxeljet VX1000 is also able to print sand casting molds and cores.

Ultem 9085 & Ultem 1010

Flame-retardant and FST-rated thermoplastics with very high heat resistance and strength-to-weight ratio. Commonly used in commercial transportation industries, especially aerospace.

ABS M30i & PC-ISO

Quickly create custom medical-grade plastic parts, tooling and prototypes with no setup costs or additional fees. Can be EtO or gamma sterilized. Click here for full list of sterilizable materials.

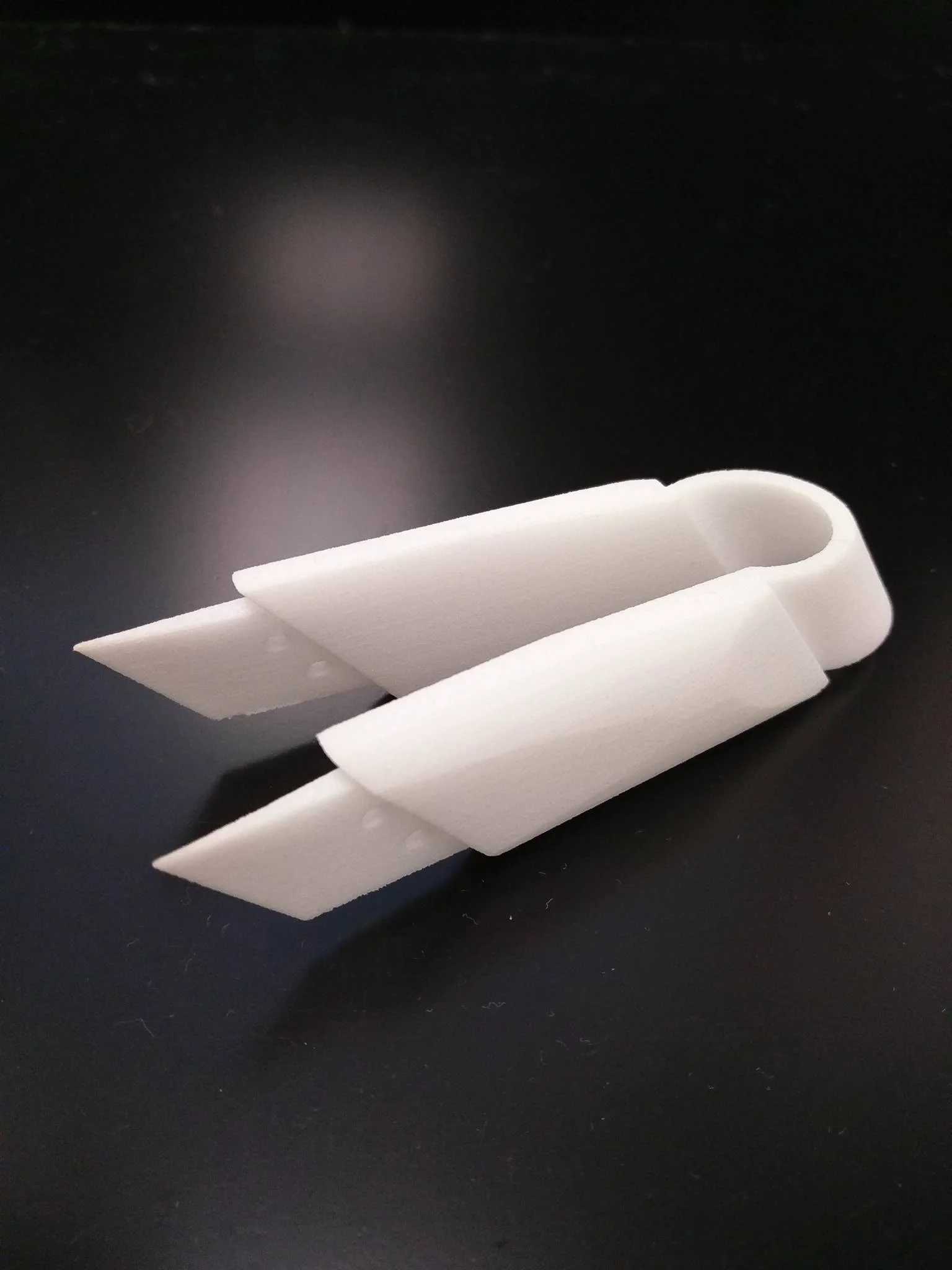

Thermoplastic Polyurethane (TPU)

Rubber-like TPU for creating flexible parts and products. Commonly used for gaskets, seals and other rubber parts. Great for small to medium runs of industrial-strength prints.

Electrostatic Dissipative ABS

Durable and affordable protection against electrostatic discharge. ABS-like mechanical quality. Consistent surface resistance with very low particle contamination.

Selective laser sintering (SLS) offers a relatively large print bed compared to most 3D printing technologies. The range of filled and unfilled nylons that are compatible with SLS allow printed parts to possess a variety of mechanical and aesthetic properties, from hard and rigid to soft and flexible. Though we recommend the HP Multi Jet Fusion for most applications, SLS can offer additional value for parts which exceed the size limits of other technologies or require specific mechanical properties.

Unfilled Nylon 2201

Smooth surface finish with strong mechanical strength and thermal resistance. Good for functional prototypes and aesthetic models.

Glass-Filled Nylon

Excellent stiffness and thermal resistance, often used as an inexpensive alternative to ABS for large, rigid parts.

Flame-Retardant Nylon

Plastic with a chemical flame retardant which protects structure against fire with a carbonating coating.

Aluminum-Filled Nylon

One of the most dense 3D printed plastics. Has a metallic appearance as well as excellent thermal and conductive properties.

Carbon-Filled Nylon

High strength-to-weight ratio and excellent stiffness. Popular in transportation industries, including automotive and aerospace.

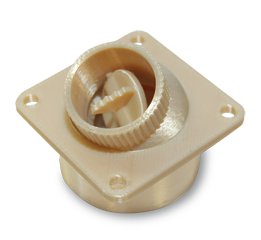

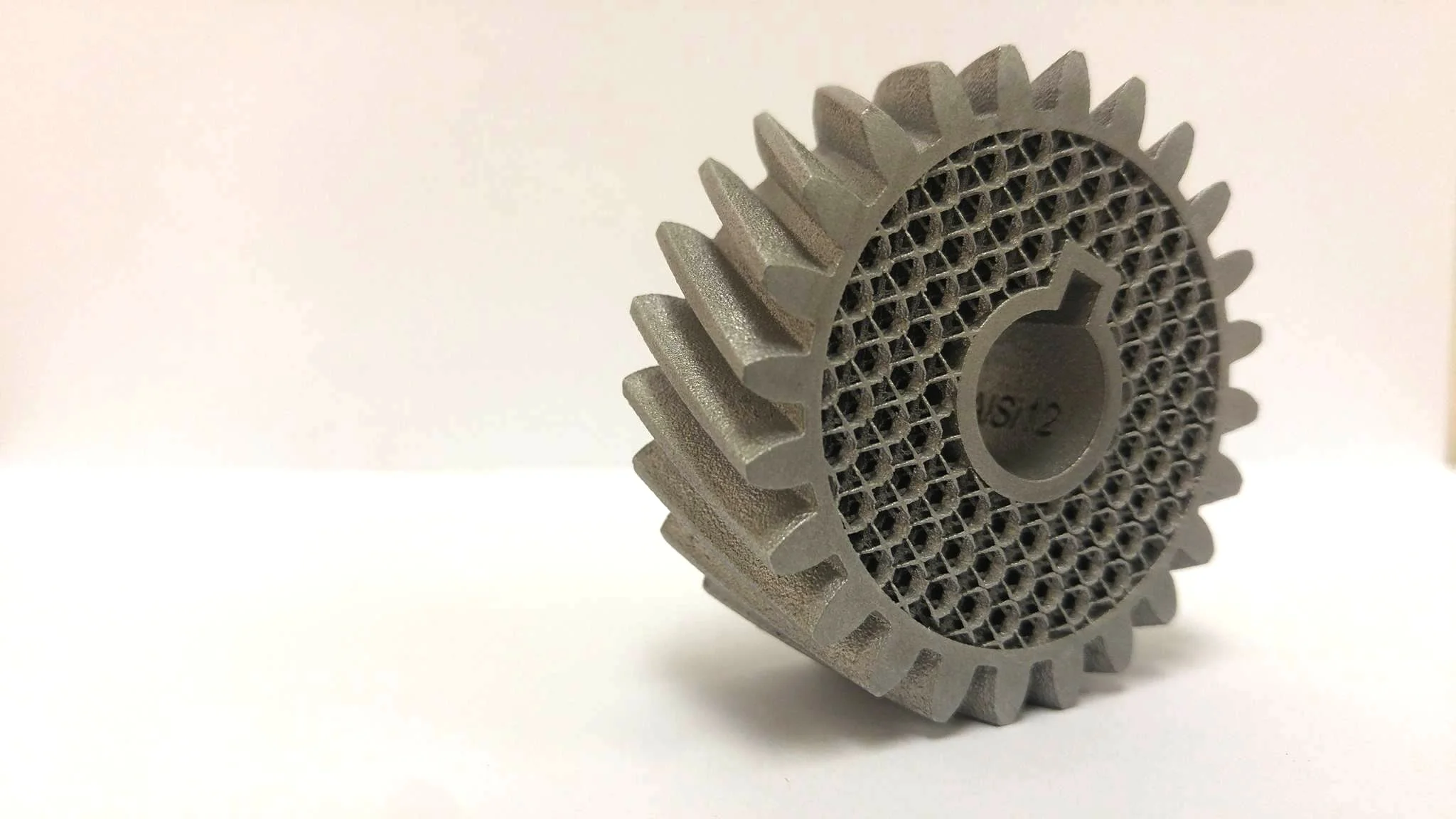

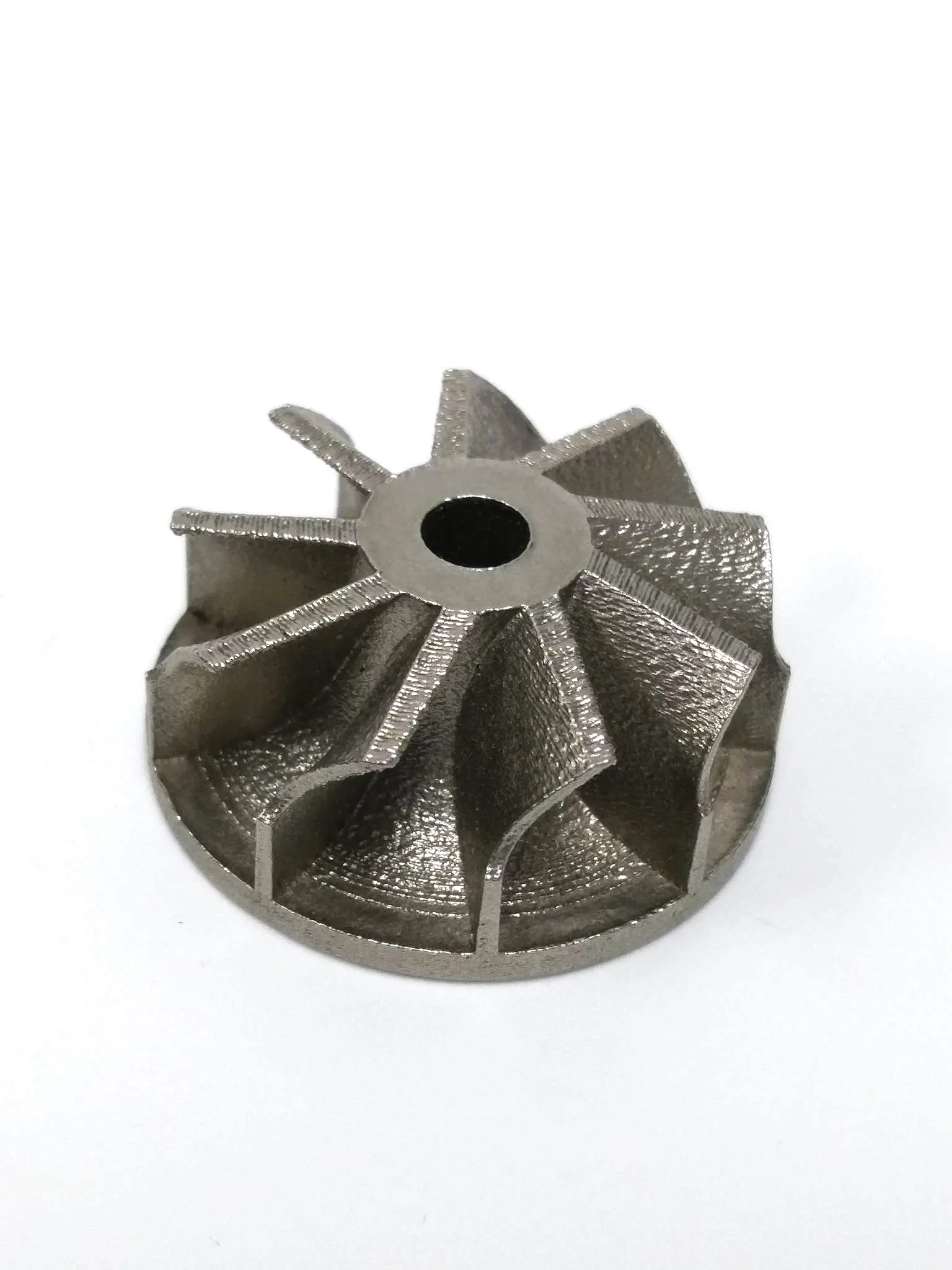

3D printed metals allow you to produce metal parts, products, prototypes and tooling with no additional setup time or fees. Like all 3D printing, direct metal printing, metal printing and direct metal laser sintering (DMLS) can produce designs with complex internal geometries like nested cores or spiral vents. 3D printed metals offer good value for functional prototypes, conceptual models or small- to medium-sized production runs.

Stainless Steel 304L

The most versatile and widely used stainless steel. Easy and consistent fabrication with good corrosion resistance and strength. Many general-purpose commercial applications.

Stainless Steel 17-4

Very high strength, heat-treated stainless steel with good corrosion resistance. Often used for cooling and aerospace applications. Meets MPIF 35 standards.

Stainless Steel 316L

Easily machined metal with high temperature resistance. The most commonly used MIM powder. Many heat-sensitive applications in aerospace, automotive and medical industries. Meets MPIF 35 standards.

316 Stainless Steel/Bronze

The best option for post-printing machining. Able to achieve very tight tolerances. High wear resistance. Ideal for tooling, fixtures and medical parts.

420 Stainless Steel/Bronze

The most cost effective Direct Metal material with high wear resistance for increased product life. Good for aesthetic pieces and high-wear components like impellers, rotors, or firearm parts

Aluminum ALSi10Mg

Lightweight metal with good thermal resistance, hardness and mechanical strength, often used for thin parts and complex geometries.

Titanium Ti64

Biocompatible metal with excellent mechanical strength and corrosion resistance. Used in medical and transportation industries.

DMLS Stainless Steel

Corrosive-resistant DMLS options include stainless steel 17-4, stainless steel 316L and stainless steel PH1. Used for high-wear parts, medical devices and more.

420 SS Bronze Alloy

Typically the least expensive 3D printed metal. Lightweight and durable parts with good surface finish. Can be annealed or non-annealed.

Cobalt Chrome MP1

Biocompatible metal with very high specific strength and corrosion resistance. Often used in medical industry for artificial joints and dental implants.

Maraging Steel MS1

Hard, strong and durable 3D printed tool steel, ideal for creating tooling, molds and other industrial-grade parts and products.

Inconel 625

Nickel alloy with superior corrosion resistance and thermal properties and good mechanical strength. Used in high-corrosion applications.

Inconel 718

Nickel alloy with excellent mechanical strength, as well as good heat and corrosion resistance. Used in high-heat, performance applications.