AM Forward seeks to encourage the uptake of 3D printing by small and mid-sized enterprises. The goal? To help secure supply chains and recharge the manufacturing industry.

5 Benefits of Part Consolidation with Additive Manufacturing

Now Hiring: Finisher/Shop Technician

3D Printing for Rapid Prototypes

The goal is faster manufacturing. The process of rapid prototyping starts with using computer-aided design (CAD) to create a digital model of an object. This model is not just a 3D drawing, it's a virtual representation of the entire piece, rendered in 3D space on your computer.

3 Benefits of 3D Printing for Companies

4 CNC Machining Trends Shaping The Industry

Press Release: Celebrating our 10 Year Anniversary

Case Study: Thermoforming Parts for Kabuki Strength’s Kratos Flywheel

Sustainable Manufacturing and Its Impact on 3D Printing

How 3D Printing for UAVs Will Pave the Way For the Future

Why Choose Jet Fusion (MJF) over SLS/Selective Laser Sintering?

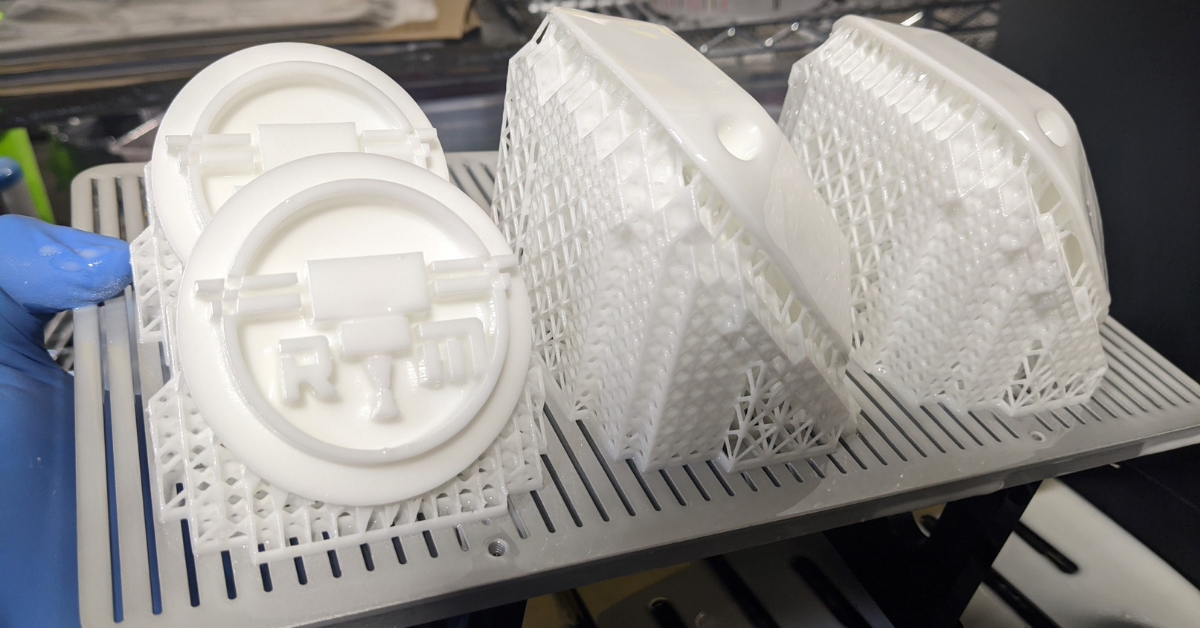

What is Stereolithography?

While the process is very simple, the results of stereolithography are limitless. SLA has become popular after the introduction of desktop SLA 3D printers.