These two technologies are the top two choices for most industrial customers when they want end-use mechanical parts.

3D Printing (Additive Manufacturing) is a Family of Technologies

When we talk about 3D printing, it is a catch-all phrase that encompasses several distinct technologies, each with its own strengths. Here are some comparisons of additive manufacturing options in plastic, metal and composites:

3D Printed Plastics

Fused Deposition Modeling (FDM)

Learn more about FDM

Standard Materials: ABS

Relative Cost: ★★☆☆☆

Machine Finish: ★★☆☆☆

ABS Prime Finish: ★★★★★

Typical Lead Time: 2-5 Business Days

Specialty Materials: PC, nylon, ULTEM and many more (See FDM page)

Relative Cost: ★★★★☆

Machine Finish: ★★☆☆☆

Typical Lead Time: 3-7 Business Days

FDM Pros: Very high accuracy on large parts, diverse materials, rigid and tough, fast turnaround, sparse fill for light weight with high part volumes

FDM Cons: Striated machine finish, low resolution on features under 0.030"

Polyjet (Objet) Printing

Standard Materials: Acrylic and polypropylene-like

Relative Cost: ★★★☆☆

Machine Finish: ★★★★★

Typical Lead Time: 2-5 Business Days

Specialty Materials: ABS-like, various elastomers and digital materials (See Polyjet Page)

Relative Cost: ★★★★☆

Machine Finish: ★★★★★

Typical Lead Time: 3-7 Business Days

Polyjet Pros: Top quality detail, best surface finish, clear material option, embedded textures, fine features, single piece mechanical assemblies

Polyjet Cons: Resins - not industrial thermoplastics, lower heat resistance, better for smaller parts

Selective Laser SIntering (SLS)

Standard Materials: Nylon and glass filled nylon

Relative Cost*: ★★★☆☆

Machine Finish: ★★★☆☆

Typical Lead Time: 5-10 Business Days

Specialty Materials: Rubber (TPU), carbon filled nylon and other composites (See SLS page)

Relative Cost: ★★★★☆

Machine Finish: ★★★☆☆

Typical Lead Time: 5-10 Business Days

SLS Pros: Real thermoplastic and thermoplastic composites, uniform matte finish, great thermal and mechanical properties

SLS Cons: Large and thick parts can warp, longer production lead times, porous material, low resolution on features under 0.030"

*In volume SLS can become one of the least expensive printing processes.

Large Format 3D Printing

Learn More about Large Format 3D Printing

Standard Materials: Epoxy infused Acrylic

Relative Cost*: ★★★☆☆

Machine Finish: ★★★☆☆

Typical Lead Time: 5-10 Business Days

Specialty Materials: Sand (Sand Casting), Low Ash Burnout Resin (Investment Casting)

Relative Cost: ★★★☆☆

Machine Finish: ★★★☆☆

Typical Lead Time: 5-10 Business Days

Large Format Pros: Largest build size of any 3D printers, cost effective for large parts, casting patterns and molds without any additional tooling

Large Format Cons: Not as durable as SLS or FDM, not intended for small objects, longer production lead times compared to smaller printers

3D Printed Metals

Note: 3D printed metals tend to be 5 to 10 times the cost of 3D printed plastics and are often more expensive than machined metals.

Direct Metal Laser Sintering (DMLS)

Standard Materials: Aluminum, stainless steel, tool steel and titanium

Relative Cost: ★★★★★

Machine Finish: ★★☆☆☆

Typical Lead Time: 5-15 Business Days

Specialty Materials: Cobalt chrome, inconel, (nickel alloy) and more (See DMLS page)

Relative Cost: ★★★★★

Machine Finish: ★★★☆☆

Typical Lead Time: 5-15 Business Days

DMLS Pros: Stronger than cast parts, works with exotic and expensive to machine metals, can make parts that are otherwise not manufacturable

DMLS Cons: Limited part size (generally under 10"), rough finish, lower tolerance than machining, generally more expensive than machining

Printed Metal

Learn more about Printed Metal

Standard Materials: Stainless steel bronze alloy

Relative Cost: ★★★★☆

Machine Finish: ★★☆☆☆

Typical Lead Time: 10-20 Business Days

Specialty Materials: None

Relative Cost: N/A

Machine Finish: N/A

Typical Lead Time: N/A

Printed Metal Pros: Half to a third the cost of typical DMLS parts, beautiful bronze polish look, easily plated, larger bed than DMLS

Printed Metal Cons: Single available material, low strength to weight ratio for metal, long lead time relative to other 3D technologies

3D Printed Composites

Colorjet Full Color Composite

Standard Materials: Full color composite

Relative Cost: ★☆☆☆☆

Machine Finish: ★★★☆☆

Typical Lead Time: 2-5 Business Days

Specialty Materials: None

Relative Cost: N/A

Machine Finish: N/A

Typical Lead Time: N/A

Full Color Composite Pros: Full gradient of 390,000 colors, generally least expensive material, fastest way to make large models, very rigid

Full Color Composite Cons: Features thinner than 0.100" can be brittle, does not have the flex of real plastic

RapidMade Helps SweetSense Make Life Sweeter for Residents in Kenya

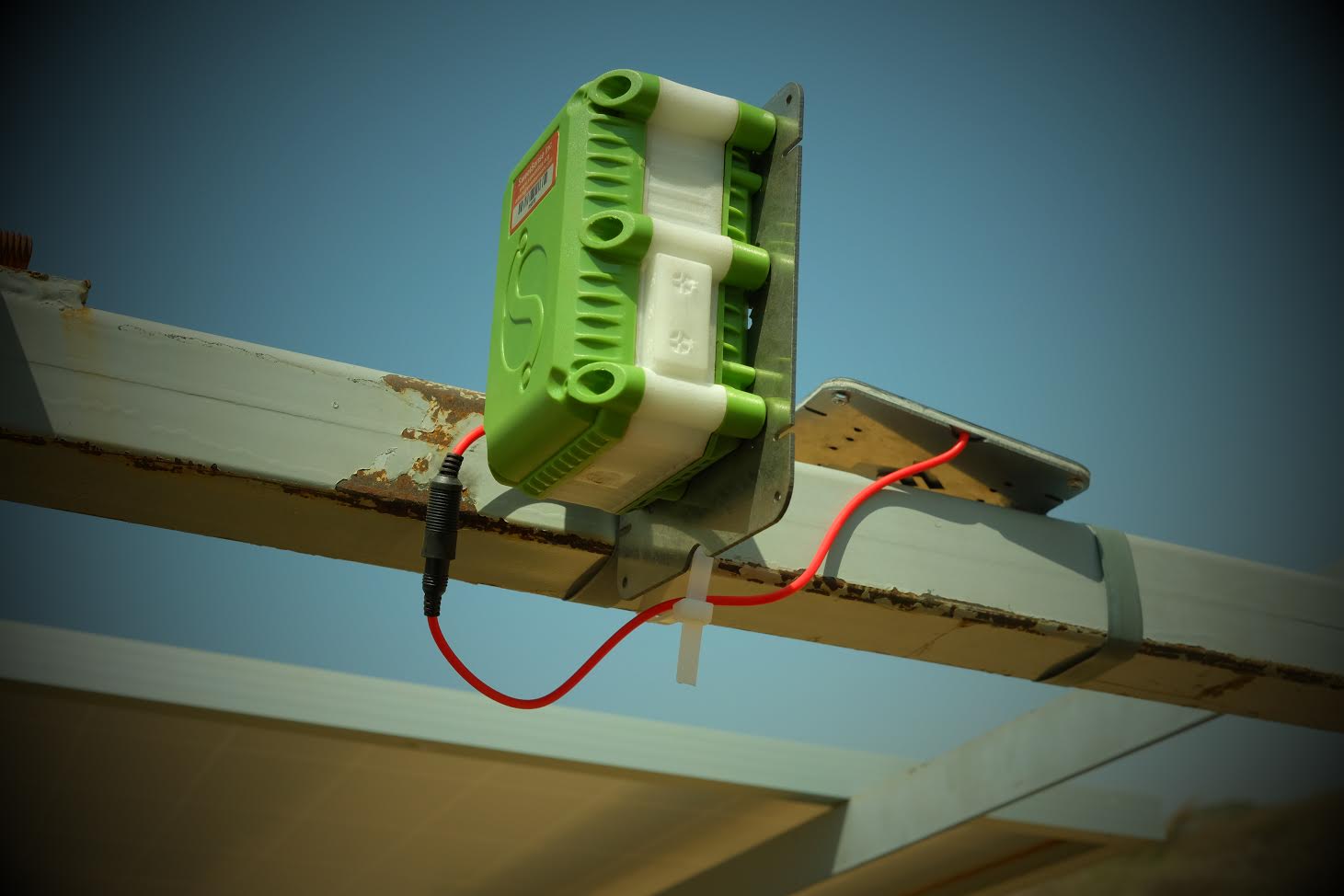

RapidMade especially enjoys working on projects designed to improve the lives of others. And we are thrilled when we get to see them "in action." Recently SweetSense asked us to 3D print SLS parts that were used to produce remote sensors in Kenya that allow residents to better maintain water supplies and sanitary latrines.

According to Taylor Sharpe, SweetSense is a "social enterprise" that is a spin-off of the Portland State SWEET Lab and partners with other agencies to provide high-tech solutions to problems faced by residents in developing countries.

“...in one case monitoring boreholes (deep water pumps that service 100s to 1000s of people) in Isiolo and Turkana counties in Kenya; and in the other case helping manage collection routines and operator issues of Sanergy Fresh Life latrines in the Mukuru informal settlements outside of Nairobi, Kenya.”

For one of its initiatives, it has partnered with Sanergy to produce a

“rugged enclosure that contains an occupancy sensor and am RFID reader, to respectively estimate the fill level of latrines before conversion to fertilizer and to give Fresh Life Operators a direct line of contact with Sanergy HQ in the case of emergencies.”

In another, the Sat Spacer, SweetSense worked with Kenya RAPID...

“RapidMade parts were used to allow SweetSense to provide satellite-based monitoring in areas with no cellular coverage.”

University of Sheffield Touts Breakthrough in High Speed Sintering (HSS)

Image Credit: 3DPrint.com

Just when you thought you'd learned all of the additive manufacturing technologies and acronyms, the University of Sheffield announces a new twist to the 3D printing process called High Speed Sintering (HSS). Like its sister technology, Selective Laser Sintering (SLS), HSS uses heat to bind layers, but instead of using a laser to melt powder, HSS relies on a carbon black ink that is applied to the powder instead. To build an object, the specialized heat-sensitive ink is sprayed in the desired shape, and when an infrared lamp passes over the bed, the ink absorbs the heat to fuse the powder.

So what makes the University of Sheffield's approach unique? They manipulate the concentration of carbon black ink to control the strength and density of 3D prints (more ink, more dense)... a technological version of 50 Shades of Grey.

According to Professor of Manufacturing Engineering Neil Hopkinson,

“We found that there is a point at which, as the ink levels increase, the mechanical properties start to reduce. This enabled us to identify the ‘sweet spot’ at which you can gain maximum strength with the minimum amount of ink. 3D printing has focused on optimising the shape of a part in order to reduce its weight and still retain its mechanical properties. Printing in greyscale will enable us to optimise the material instead, in a process that would be feasible for commercial manufacture. And by making parts with different densities out of one material, we can also make recycling more straightforward.”

Research continues to develop a more sophisticated printer that is capable of using a true gray-scale to replace the current dot application method and exceed the 40% density variation they can now achieve.

Here's a video on 3DPB.com that describes the process.

What's the Difference Between SLS and SLM?

3D Printed Food: A Sweet Idea

3D Printed Mesh Egg, work of Julian Sing (http://www.3dprintingpin.com/3d-printed-sugar-models-made-from-sugar/)

Any time I see an article about 3D printed food, I’m drawn to it… after 18 years with Nabisco, it’s a habit. Lately, I’ve been speculating how the technology will change our approach to food processing, especially baked goods. And despite my enthusiasm for additive manufacturing, I’m not sure the industry is going to widely adopt 3D printing – it took YEARS for them to abandon lard for soy bean oil. Maybe to appreciate my skepticism, you have to understand:

1. How baked goods are typically made

2. Where most challenges occur in the process

Just like at home, the first processing step is mixing. You take your ingredients (several ingredients - all of which have different handling requirements and product characteristics) and mix them together in a methodical way. The methodology – and technology - differ based on what is being made. So, I can’t see a near-term solution to this challenge. Other than automated delivery or continuous mixing, traditional manufacturing techniques are likely to remain dominant.

After mixing, you turn the dough into cookies or crackers. Here’s the next challenge, cookie doughs and cracker doughs are generally very different and – yep - have different handling requirements and product characteristics. Cracker doughs first have to be sheeted and layered to ensure the crackers are flaky. Afterward, cutters form the crackers. If they’re round, there will be excess dough but it is immediately reused. Salt is then applied. Cookie doughs are mostly soft and so are deposited or molded into shape – already efficient processes that generate little scrap if done right. So if food processing is already efficient and generates little scrap, there’s less advantage to adopting additive manufacturing techniques.

Next, the raw dough pieces are baked... typically by continuous baking, often on ovens the length of football fields with hundreds of top and bottom burners that are 5+ feet wide. As the product travels through, it is baked, usually in 3 -7 minutes, and afterward, if needed, coated with toppings like oil. The continuous nature of baking is also very efficient – if done correctly – and again, makes 3D printing less practical. If it is an iced cookie then the coating is applied through extrusion in a manner somewhat similar to Fused Deposition Modeling, the warm icing is applied and quickly hardens as it cools.

Probably the biggest obstacle is existing infrastructure. The largest food processors have millions committed to traditional manufacturing and are not likely to radically transition to additive manufacturing. Yes, Hershey plans to 3D print custom chocolate designs and Contractor has “created a proof-of-concept printer that can print chocolate onto a cookie” but current chocolate processing is already an additive process: The liquid is poured into a mold and hardens as it cools. Where it differs is the resulting chocolate is a standard design and not customized.

But let’s consider how and when 3D printing might work.

If you were observant, you picked up that cracker doughs are layered (laminated) before being cut, so one could print the doughs and produce a cracker ready to be baked, but not at the speed currently required of food processors.

We could also theoretically laser sinter a cookie or cracker dry mix to form the product, but without oil or water, it probably wouldn’t taste great – and then there’s the flammability (explosiveness) of flour and sugar powders when subjected to sparks. So that might be a problem…

Then there’s binder jetting. This technique is actually being used by Julian Sing to 3D print objects in sugar:

According to Michael Franco “Combining his love of model making and baking, Sing modified a ZPrinter 310 Plus from 3D Systems to be able to produce creations out of sugar and water. The printouts aren't entirely edible yet because of a secret involved in the process that Sing wouldn't share, but they sure look good enough to eat.” I found this observation very humorous for two reasons: I know what’s typically used to bind 3D prints – and it is definitely NOT edible, and I can remember times during baking when sugar hardened into shapes on its own – and that was NOT very fun to deal with.

What about vat photopolymerization – well not the material - but the technique? I suppose a process might be developed to expose layers of a liquid batter to light in a way to bake it, but again I can’t imagine it would taste very good or be efficient enough.

So why even consider these approaches? Well space limitations might be one reason. It certainly is a consideration in NASA funding Contractor’s work. The schematic shown actually reminds me of existing food processing equipment – large holding tanks of ingredients from which the raw materials are drawn to be mixed or deposited. As I mentioned, commercial ovens can span hundreds of feet and house as many burners. Coming up with a process that could handle baking on the same scale might be appealing.

But baking is only half the battle. Once the product is made, it still has to be packaged - which can be a 2D printed nightmare... but that's another story altogether.

RapidMade to Print 3D Prosthetic Hand

In the field of 3D printing, medical advances have arguably received the most press, with good reason - 3D printed prosthesis are changing lives. The London Science Museum is now featuring an exhibition that highlights one great example, a 3D prosthetic arm designed and manufactured by the Engineering and Physical Sciences Research Council's Centre for Innovative Manufacturing in Additive Manufacturing. This prototype features "customised prosthetics with electronic moving parts and nerve endings, created by the research group at the University of Nottingham."

Unfortunately, the cost of high tech prosthesis like this is a serious drawback , especially when children are involved. Kids need a medical device that won't cost an ar - well you know the expression - their changing bodies require a less expensive alternative that can be replaced as needed to accommodate growth.

RapidMade is very excited to be partnering with a 13-year-old Oregonian who has a congenital amputation to customize, print and fit an inexpensive hand for him to evaluate. Alex and his mom, Lori, visited us earlier in April to discuss the project and provide his measurements. 3D printing will allow us to size the prosthetic to match his hand instead of a "one size fits all" device. David, our engineer, has already begun printing parts and assessing design features. RapidMade hopes to make plastic prosthetic hands out of ABS plastic using fused deposition modelling (FDM) and Nylon using Selective Laser sintering (SLS) in order to better meet patients' specific needs for price and quality.

We are grateful to Paul McCarthy who designed and shared the original version we are evaluating. He and other designers have made their work available for free through open sourcing to drive down costs. As 3D users already know, it is often the product design phase that is the most costly and time consuming, so to have a ready-to-print CAD file is an enormous benefit.

If this trial is successful, we hope to become part of a network that provides low-cost prosthesis to others who are similarly challenged. Stay tuned for updates on our progress...

3D Printed Casts

The technique is antiquated and could use a little something of a shake up thanks to new technology.

Setting castings in plaster is centuries old and has a variety of uncomfortable problems. Scanning and imaging of the body are common place in the medical field in order to diagnose injuries and illnesses, but the ability to create prosthesis and custom fixtures directly from those scans is brand spanking new, from printed bones and teeth implants to entire artificial limbs. The parts either fit to the contours of your body or are exact replicas of the body part which they replace.

This technique now produces a superior cast taken directly from a 3D scan of the broken body part and 3D prints a cast from the digital negative. The cast is designed with snap fits which enclose the arm, keeping it from moving, but making it accessible to air and hands. Much more comfortble.

Just another simple example where the medical field can benefit from applying new technologies (additive manufacturing/3D printing) to ones that are already pervasive in the medical field (3D scanning and imaging.)