AM Forward seeks to encourage the uptake of 3D printing by small and mid-sized enterprises. The goal? To help secure supply chains and recharge the manufacturing industry.

3D Printing for Rapid Prototypes

The goal is faster manufacturing. The process of rapid prototyping starts with using computer-aided design (CAD) to create a digital model of an object. This model is not just a 3D drawing, it's a virtual representation of the entire piece, rendered in 3D space on your computer.

3 Benefits of 3D Printing for Companies

What is Stereolithography?

While the process is very simple, the results of stereolithography are limitless. SLA has become popular after the introduction of desktop SLA 3D printers.

An Introduction to SLA 3D Printing

A Guide to Bulk 3D Printing

Why Work with RapidMade As Your 3D Printing Partner

We are more than just a manufacturer, engineering service or 3D printer; we treat every project as if it were our own – with the utmost care and attention to detail. Why? Because every business has its own unique drivers, goals, and needs – and your projects deserve to be custom-tailored to exceed your expectations.

Commercial 3D Printing Is Paving The Way for Innovation

Why Design for Additive Manufacturing (DfAM)?

Additive manufacturing, also known as 3D printing, has rewritten the rule book for modern design and engineering. 3D printed parts are durable and inexpensive at low volumes. They:

Achieve previously impossible complex geometries

Do not require any tooling or other start-up expenses

Reduce initial production costs

Enables on-demand manufacturing

But the best design practices for traditional manufacturing technologies do not apply directly to additive manufacturing, and, in fact, can prevent users from getting the greatest value out of their 3D printing operations.

To Design for Additive Manufacturing (DfAM):

Start early in the Product Development cycle to include the benefits of AM

Factor in mechanical differences; 3D printing can produce shapes not possible with injection molding or machining.

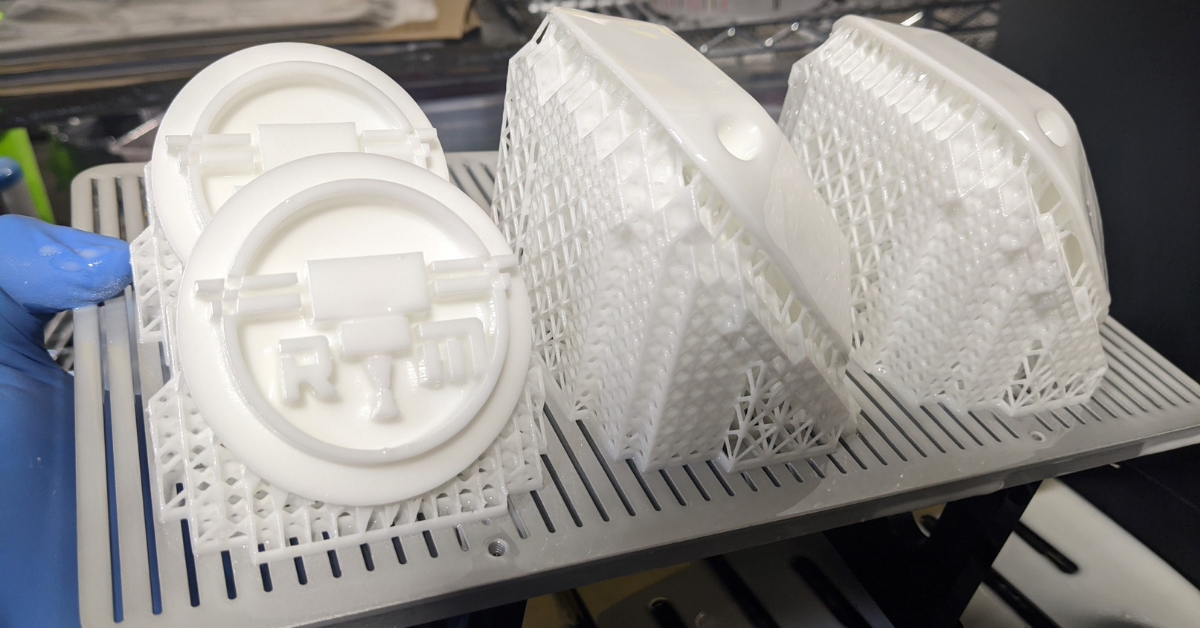

Design latticed interior structures to reduce part weight and volume without sacrificing strength

Change part orientation to manipulate part rigidity levels

Think about ways to increase build density to increase part quantity and cost.

Design for Additive Manufacturing Workshop with HP and RapidMade

Learn how innovative design and HP Multi Jet Fusion 3D printing can improve part quality, reduce costs, and speed up production.

Where: RapidMade | 15883 SW 72nd Ave, Tigard, OR 97224

When: Tuesday, April 9th, 2019 | 9AM - 4PM

Additive manufacturing is rewriting the rulebook for product design, which is why RapidMade is teaming up with HP for a free all-day event about design for additive manufacturing (DFaM) on the HP Multi Jet Fusion. Engineers and product designers are invited to join us for a special workshop led by additive manufacturing experts to learn more about how to get the most from 3D printing.

Here's what you'll learn:

Why HP used the Multi Jet Fusion instead of injection molding to manufacture over 140 functional parts used in each of its new MJF 500/300 3D printers

Identifying applications for additive manufacturing across your product lifecycle

Training on the fundamentals of effective design for MJF

Design strategies for MJF process optimization

How the materials behave and what to consider when designing for each of them

New design paradigms for additive manufacturing and the required mindset change

Designing for value maximization (process and cost)

Training on the fundamentals of effective design for MJF

Live Design for Additive Manufacturing (DfAM) demo and application examples to inspire you

This free event will feature breakfast and lunch, as well as the opportunity to tour our facilities and consult directly with specialists from RapidMade and HP.

Don’t miss out on this exciting opportunity! Registration is limited, so click the link below to reserve your spot today.

REGISTER HERE

Agenda

8:30 – 9:00 AM Breakfast

9:00 – 9:15 AM Welcome & introduction

9:15 – 9:45 AM Multi Jet Fusion (MJF) basics

9:45 – 10:15 AM Why 3D & case study of HP's adoption of Multi Jet Fusion technology for production parts

10:15 – 10:30 AM Break

10:30 – 11:30 AM Deep dive on designing for additive manufacturing – strategy, guidelines, materials, considerations, machining & threads, bonding, process control, etc.

11:30 AM – 12:00 PM Cases for tooling and final part production – urethane casting, thermoforming, fluidics management, industrial applications & electric vehicle examples

12:00 – 1:00 PM Lunch

1:00 – 3:00 PM Applications discovery workshop

3:00 – 4:00 PM Consult with HP and RapidMade experts on your parts

We look forward to seeing you!

Can't attend?

Get in touch with our 3D printing experts here.

University of Pittsburgh Awarded Grant to Improve 3D Printing of Tungsten Carbide

Carbide Parts provided by General Carbide Corporation (photo chredit University of Pittsburgh)

My alma mater in home town Pittsburgh continues its research in additive manufacturing. One of its latest projects involves evaluating the effectiveness of binder jet 3D printing technology to produce robust tungsten carbide parts. Researchers hope that binder jet-based 3D printing will overcome a challenge often encountered in fusing layers by “energy beam-based 3D metal printing” which can cause part failure due to rapid heating and cooling.

Pitt’s industry partner is General Carbide which is located in Pennsylvania. While the partners don’t specifically identify the 3D printer being used, researchers can be seen gathering around an ExOne (headquartered close to Pittsburgh) printer, so that would be a logical choice. Good luck Panthers.

Oregon Business Magazine's Manufacturing Issue Highlights Gender Gap

RapidMade CEO Renee Eaton

Kudos to Oregon Business Magazine for its feature, Women’s Work, which details the chronic gender gap that continues in manufacturing. The article is based on interviews with female professionals in trade organizations, manufacturing firms, and higher education.

Together they show how improving gender representation requires a concerted approach from across the industry to reshape an institutionalized culture of gender-based segregation and redefine archaic norms of what work women can and cannot do.

Strategies proposed include:

Advising businesses that diversity will ease the labor shortage and improve the bottom line.

Promoting manufacturing careers to female students and professionals.

Providing supportive networks, like Women in Manufacturing and Oregon Tradeswomen, to help women secure employment and businesses find and retain female employees.

Breaking down the “bro culture” prevalent in manufacturing.

RapidMade CEO Renee Eaton, a Women in Manufacturing chair of its Oregon chapter was among the women featured in the article. RapidMade is a Portland-based additive manufacturing (3D printing) and engineering services firm.

Women in Leadership Forum Prompts Lively Discussion

RapidMade’s CEO Renee Eaton recently spoke at the University of Portland’s Women in Leadership Forum. The event “connects UP students with women who are leaders in the greater Portland community. The forum is a place for sharing stories, building connections and supporting” leadership development.

As a former university instructor at UP’s business school, Renee was thrilled to return to campus, catch up with former colleagues and meet with students, faculty and staff. She described her career path, lessons learned and starting a business in 3D printing (additive manufacturing) and engineering services.

RapidMade CEO to Speak at University of Portland's Women in Leadership Forum

Renee Eaton, RapidMade’s co-founder and CEO, will speak at the Women in Leadership Forum next Wednesday, November 7 from 7 - 8 PM. The free event is being held at the University of Portland’s Pamplin School of Business which is sponsoring the evening’s discussion.

The Women in Leadership Forum connects UP students with dynamic women who are leaders in the greater Portland community. The Forum is a place for sharing stories, building connections and supporting the development of women in leadership.

Prior to launching RapidMade, a 3D Printing (Additive Manufacturing) and Engineering Services firm, Renee Eaton was a university instructor at UP where she taught management classes for almost 8 years, so the engagement is a welcomed opportunity to return to campus.

HP Jet Fusion: Have it All - Better, Stronger, Faster, Cheaper Prints

Life is often filled with compromises. If you want something faster, you have to pay more or settle for less. If you don't want to pay a premium, then you have to wait or compromise on quality. Not any more...

The HP Jet Fusion's cutting-edge technology allows us to provide:

Superior surface finish, feature detail and mechanical properties to other printed plastics including Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM)

Isotropic mechanical properties and fully dense parts ensure balanced strength and durability in every axis

High chemical and heat resistance

High part accuracy of +/-0.008"

VESTOSINT is a modified polyamide powder (Nylon, PA-12 - click here to see data sheet.)

Get durable, accurate and repeatable nylon products at or below machined and injection-molded prices - in a fraction of the time.

Let us show you how.

K9 Helm Shields Hard-Working Dogs from Serious Injuries

RapidMade often has the privilege of working with some extremely innovative designers and entrepreneurs. We love collaborating with clients to fast track their ideas from conception to production. We never tire of seeing revolutionary products being 3D printed! One of our favorites is K9 Helm whose Trident helmets safeguard dogs committed to serve and protect others... If you love dogs, you will love this video and the company's credo...

“The Trident wasn’t designed on a computer. It was hand sculpted as a flowing, organic shape that works harmoniously with the anatomy and movement of the dog. Technology has its place, of course. Original forms are scanned, transformed into CAD models, and given physical form using HP Multi-jet Fusion 3D printing — ideal for small batch production where high precision and maximum durability are desired.

The result is our Trident K9 Tactical Helmet. Made for dogs who engage in dangerous work, it’s our tribute to them and a constant reminder to us — never stop innovating, never compromise, and never, ever give up.”

Businesses Celebrate Holidays with Custom 3D Printed Gifts & Promotionals

Businesses looking to create novel gifts and promotional giveaways are increasingly turning to 3D printing to customize - and maximize - their marketing efforts. Consider these benefits:

- Pens and magnets are boring and forgettable. Make a promotional giveaway your customer has never before seen.

- Come to us with nothing but an idea for a promotional product, and we can take care of the rest.

- Personalize your giveaways to the exact customer you are handing it to with custom messaging.

- Many promotional products require expensive tooling and long lead times to accomplish - RapidMade can make your promotional products in a week or less.

- Get your products in front of customers where it would otherwise be difficult or impossible.

- Customize marketing materials with logos and designs.

- Infinite customization to achieve the exact effects you desire.

- Get concept models in front of customers early in the product development cycle to get feedback before spending too much money on the wrong track.

- Get tangible products in your customers hands instead of a 2D computer image.

Contact us to learn more.

RapidMade Clients Named PBJ Small Business & Innovation Award Winners

Congratulations to Innovarai and Madorra Medical who are among Portland Business Journal's 2017 Small Business & Innovation awardees! Their achievements will be recognized and their products showcased on November 1st from 5:30 p.m. - 7:30 p.m. at the Portland Hilton Hotel.

Rapid prototyping and low-volume production, made possible through 3D printing (additive manufacturing), are lowering the barriers to entry for entrepreneurs and start ups. These advanced manufacturing technologies lower costs, reduce lead times, and optimize designs, making product launches more affordable and timely.

Hometown Pittsburgh's High-Tech Make Over...

Growing up in Pittsburgh, if you weren't directly connected to the Steel industry, you complained about the rotten egg smell and pollution. But when the industrial giants went silent in the 70s and 80s, the complaints shifted dramatically to the economic tragedy that was unfolding - the flight of life-long residents and well-paying jobs. Rhetoric from the recent election aside, Pittsburgh's manufacturing base is both alive and well...

“The Pittsburgh Regional Alliance (PRA) recently reported that in 2016 the manufacturing sector accounted for the most investment dollars ($6.1 billion), the most deals (50 companies expanding or relocating), and the most new and retained jobs (3,667).”

But as we've continued to see, the type and number of jobs that have been created don't resemble those of the steel-era in any way.

“Manufacturing is the most active sector in southwestern Pennsylvania,” explains PRA President David Ruppersberger. “But as technology and automation continue to transform this legacy sector, the reality is that manufacturing facilities will be smaller-footprint, high-efficiency environments where fewer workers, with advanced skills including STEM proficiency, will produce more goods. This is a trend that won’t reverse at any time in the foreseeable future.”

Hearing of Pittsburgh's adoption of additive manufacturing and other advanced technologies is encouraging if the resulting economic turnaround benefits the greater community.

Congratulations to Paper Packaging on Retirement After 53 Years in Business

Paper Packaging, Pittsburgh landmark, closes this week

This week, Paper Packaging closes after 53 years in business. Why would RapidMade be marking this occasion you may ask? Its founder, Dan Unico, who worked every day in 2D printing and box making, is the father/grandfather of three of RapidMade's owners.

Dan, who also turned 90 this month, will continue to work along with his wife Joan, 85, and two sons Ken and Mark to dismantle, crate and ship equipment to new owners. In the spring, they anticipate - finally - retiring. Maybe...

Dan and Joan taught us that starting a business was - and is - a path to a better life. And we learned that lesson at an early age. As children, we would play in the factory, sometimes doing odd jobs until age and experience allowed us to "graduate" to working on the various print and die-cutting machines. This was NOT additive manufacturing. The work could be hard, dirty, and monotonous.

It is a testament to Dan that his wife, three of his four children, one son-in-law and one of his grandchildren (so far) has chosen manufacturing as a career. That is a legacy one can be proud of. Happy Birthday and Happy Retirement!

congratulations!