BY THE NUMBERS

17.4 million: Jobs supported by manufacturing in the United States

12: The percentage of manufacturing in the nation's GDP

$77,000: The average salary of manufacturing workers

$60,000: The average salary of entry-level manufacturing engineers

17: The percent of Americans who view manufacturing as a viable career choice

Source: National Institute of Standards and Technology, courtesy of Orange Count Register

My parents and brothers own a small box-making plant in Pittsburgh. When I was young, we would play in the scrap piles, sweep the floors, and do odd jobs to pass the time while our parents worked. Because of this unique experience - and because Pittsburgh was a major steel producer - I knew that manufacturing was a good career choice - if you could get the work. Unfortunately, it earned a bad reputation in the 70s, 80s, and 90s as more companies offshored and consolidated their production facilities. I myself left the field to teach when I had to oversee Nabisco's Pittsburgh plant closing.

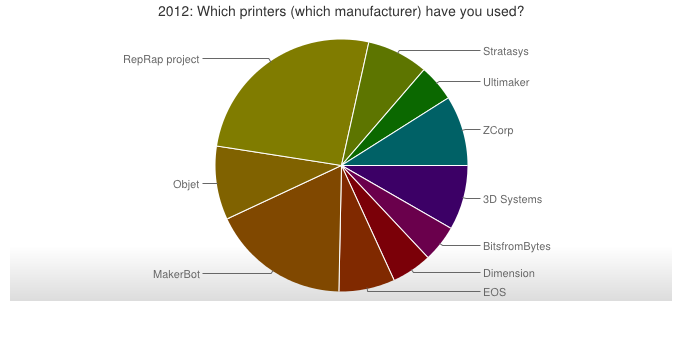

This experience is one reason I'm very excited about Additive Manufacturing (3D printing). It uses advanced technology, requires high-skilled labor and conserves raw materials... things I hope will attract another generation of U.S. makers... but first, this generation will need to learn the skills required to design, scan and make 3D printed prototypes, parts, tools and models. Increasingly, schools, like some in Orange County, recognize the importance of ensuring enough workers have those skills.

According to Orange County Register reporter Tomoya Shamira, the Dean of the UC Irvine School of Engineering Dr. George Washington describes his students' experiences,

"Students at UCI receive training in a host of additive manufacturing technologies such as selective laser sintering and stereolithography."

And this is fueling an interest in manufacturing...

"CI engineering professor Marc Madou said 3D printing is helping young people become interested in manufacturing, partly because they can turn their design into a physical model quickly."

But not all jobs will require an engineering degree which highlights the need to partner with local community colleges as well...

"While advanced technologies are changing the manufacturing landscape, there’s growing demand for experienced welders and machinists as U.S. companies are bringing their manufacturing back home. Two-thirds of manufacturers said they couldn’t find qualified workers, according to a survey conducted by the Manufacturing Institute and Deloitte Consulting."