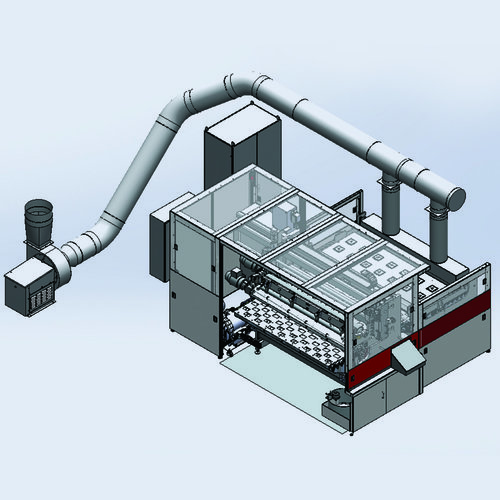

Today, it is too easy for firms to become dangerously dependent upon their suppliers. Imagine that a key distributor goes out of business or a critical supplier stops making spare parts. What happens when your supplier has your tooling, and you need to modify it? When your machine breaks down, and you need to replace the part, you don’t want to learn repairs are no longer possible - orders are backing up; production is at a standstill, and you are stuck scrambling to find an alternative. Even if you find another supplier or new equipment, you’ve already spent considerable time and money, something every business and entrepreneur has little to spare.

Now imagine an insurance policy that guarantees that no matter how old the part or obscure the producer, you know that the part can be made and the job can get done with little delay. How? Scanning and converting parts and products into digital 3D images reduces your dependence on unresponsive suppliers.

Digitization allows companies to:

Create a catalog library or parts inventory.

Find spare or obsolete parts.

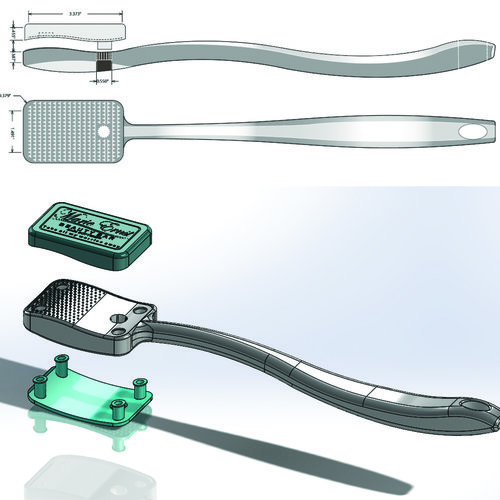

Reverse engineer an existing product or part.

Replicate a new product.

Rapidmade, renowned for its 3D printing, scanning services and engineering capabilities, efficiently and effectively renders these services for Fortune 50 and small start ups alike.

Why use us?

Professional 3D laser scanners are able to capture fine details and are not susceptible to issues with reflection, thickness, and color.

Our software can accurately smooth and sculpt the part allowing you to have consistent quality.

We ensure that there are no errors and can often print the part for assurance.

Rapidmade offers cost effective and competitive pricing schemes that include a quantity discount: having multiple parts scanned at the same time allows us to offer an inexpensive 3d scanning option.

Having a digital parts catalog liberates you from unresponsive suppliers. You insure your assets; why not ensure that your business is safe by digitizing critical parts?

Contact us to learn more.