We've blogged a few times about using additive manufacturing in construction. Given the labor and time intensity around home building, entrepreneurs see the promise of automating this industry through AM. There are a number of approaches being developed. In China, they are 3D printing walls, allowing them to erect simple homes in a day. The D Shape printer, which uses a binding technology to create structures from sand, is touted as an alternative to Portland Cement, and others have even printed elaborate structures from SLS plastic.

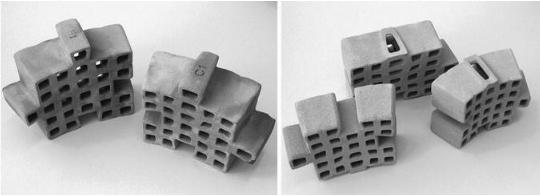

Alternatively, a group of researchers from Sabin Design Lab, Jenny Sabin Studio and Cornell University have 3D printed ceramic blocks designed to fit together without needing mortar. PolyBricks, which are produced on a ZCorp 510 powder-based printer, are seen as a hybrid method that optimizes the benefits of both traditional and additive manufacturing in home construction:

“Seeking to achieve a system that required no additional adhesives or mortar, we looked to traditional wood joinery techniques as a means of interlocking adjacent components. We developed a customized tapered dovetail in which the direction and severity of the tapering is dependent upon the local geometric orientation of each component; the tapering of the dovetail is based upon the slope of the surface being generated such that the narrow end of the tapering is always at the lower face of the generated surface. Thus, the force of gravity locks adjacent components together...

The team believes it has "effectively designed a system for 3D printing mortar-less ceramic brick assemblies at scales and in materials well beyond existing constraints of additive manufacturing technology.”

This conclusion intrigues me. Given the number of bricks required to construct a typical home, the time needed to 3D print and post process most prints, and the material costs of ceramic powder, I'm wondering how they anticipate achieving these economies of scale to compete directly with brick and mortar construction.

[Sources: 3Dprint.com and 3D Printing and Additive Manufacturing]