When it comes to manufacturing technologies, it can be tempting to want to find one perfect solution that works for every situation. In practice, however, choosing the right technology for a given project is dependent upon the project’s particular demands.

In the cases of injection molding and 3D printing, both offer unique strengths. Rather than one being superior to the other, their differences actually compliment each other and can be used in conjunction during the development and manufacturing of the same project.

Injection Molding: High-Volume Plastic Manufacturing

Injection molding is one of the oldest industrial technologies for high-volume plastic manufacturing, and there’s a reason it’s been at the top for so long. It produces high-quality parts with tight tolerances and offers excellent value for larger quantities of units.

At the same time, injection molding requires molds which can cost thousands of dollars and take weeks or even months to produce. Once the molds are produced, individual parts cost very little to manufacture. As a result, injection molding is very cost-effective above certain volumes of parts but can be prohibitively expensive for smaller runs.

3D Printing: Fast, Inexpensive and Highly Customizable

Compared to injection molding, 3D printing is a much younger technology which was initially used chiefly for prototyping and product development. With modern advances, it has become an excellent option for many full-scale manufacturing projects as well.

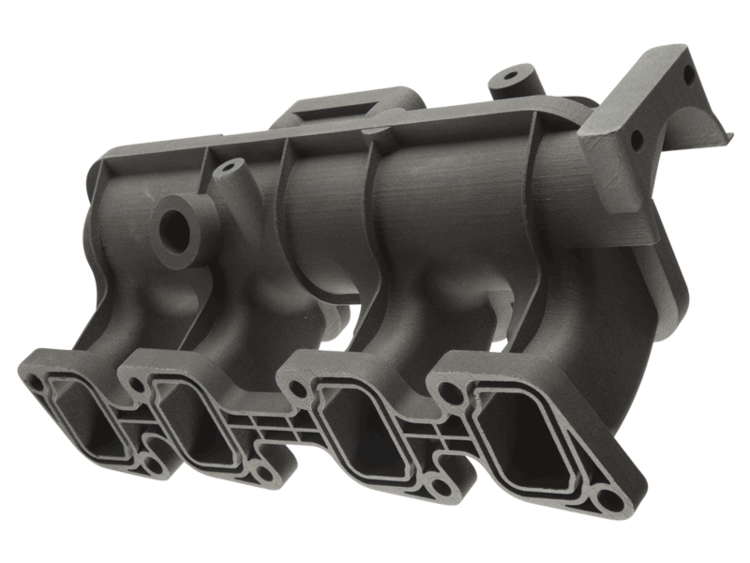

Unlike injection molding, 3D printing does not require any tooling or additional setup costs. Because of this, it is substantially faster and less expensive than injection molding for small to medium volumes of parts. Furthermore, 3D printing is able to produce complex geometries, internal features and organic shapes in a way that would be impossible to achieve with injection molding.

When is 3D Printing Cheaper than Injection Molding?

When it comes to assessing whether 3D printing or injection molding is a better fit for a given project, the biggest factor is often the number of units being produced. The exact tipping point for cost per unit depends on the part itself, but typically, orders of smaller than 1,000 to 2,000 units will be cheaper to 3D print, while orders larger than 2,000 units will be more well-suited to injection molding.

Although injection molding is quite time-consuming and expensive to get started, it is very cheap once it is up and running. As production quantity increases, the initial setup costs are distributed across more units, leading to an lower cost per unit. With 3D printing, on the other hand, the cost per unit is constant no matter how many units are made. As the number of units increases, the cost per unit of injection molding will eventually become lower than the cost per unit of 3D printing.

3D Printing and Injection Molding for Product Development

Fortunately for manufacturers everywhere, we don’t have to choose sides but can take advantage of the complementary nature of the two even within a single product cycle. Since injection molding requires expensive tooling that cannot be modified after the fact, it is not well-suited to product development and iterative prototyping. Instead, 3D printing offers excellent value and unmatched speed for rapid prototyping.

Printing a new prototype is as easy as changing a digital model, and modern 3D printers like the HP Multi Jet Fusion can imitate the mechanical strength, finish quality and tight tolerances of injection molded parts. 3D printing can even be used to create patterns and tooling for urethane casting as a fast alternative to injection molding for prototyping or medium-sized production runs.

Finding the Right Manufacturing Technology for Your Needs

When it comes to evaluating whether 3D printing or injection molding is right for your project, the main consideration is the volume of parts you’re looking to produce. Simply put, 3D printing offers better value for small to medium runs, while injection molding is most cost effective for larger runs. Additional considerations like the complexity or customizability of your design can tip the balance further in favor of 3D printing.

More than anything, however, it's important to realize that there may be room for both technologies in any given supply chain. By playing into the strengths of each technology, manufacturers can get the best of both worlds and maximize their competitive advantages.

At RapidMade in Portland, OR, we work hard to find the best technologies for our clients’ unique needs for custom product development and full-scale manufacturing. Our manufacturing and engineering services include 3D printing, injection molding, urethane casting, vacuum thermoforming and more. Click here to learn more about our services and get started on your custom manufacturing solution today.