Selective Laser Sintering (SLS)

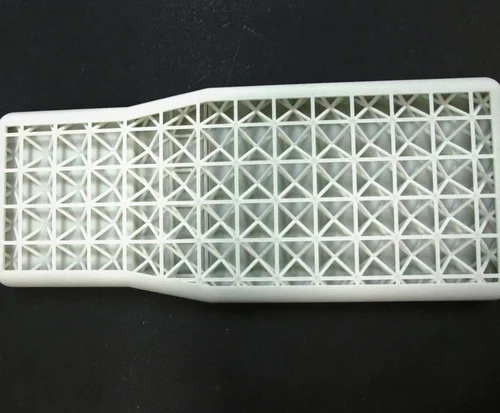

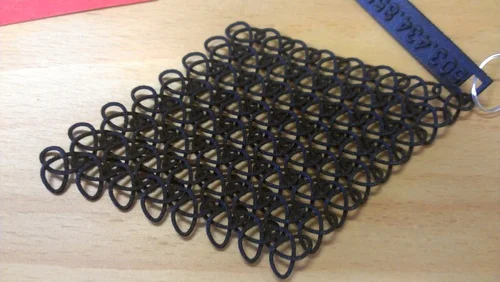

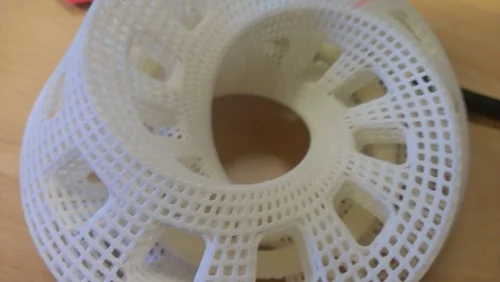

Selective laser sintering (SLS) uses a laser to solidify, or sinter, powdered nylon into cross sections. Guided by a 3D model, SLS sinters layer upon layer until the product is complete. 3D printed nylon products created with SLS are lightweight and durable, able to be made hard, tough or flexible as needed. The plastics used in SLS are food safe and do not leach. With a relatively large bed, SLS is a well-suited to 3D printing a large volume of plastic parts in single runs.

3D printed plastics are durable, inexpensive and quick to produce. They also eliminate many of the design restrictions of traditional manufacturing. To learn more about our other 3D printed plastic options, check out our HP Multi Jet Fusion 3D printing services or our 5-Minute Buyer’s Guide.

SLS Design Guidelines

Please note that these are are guidelines, not hard-and-fast rules. Follow these, and you should be in pretty good shape. We'll let you know if we see any problems with your design.

| Parameter | Inches | Milimeters |

| Maximum Part Size | 27.6 x 15 x 22.9* | 700 x 380 x 580* |

| Expected Tolerance | +/- 0.3%** | +/- 0.3%** |

| Minimum Supported Wall Thickness | 0.030 | 0.75 |

| Minimum Unsupported Wall Thickness | 0.030 | 0.75 |

| Minimum Supported Bosses | 0.030 | 0.75 |

| Minimum Unsupported Bosses | 0.040 | 1.00 |

| Minimum Embossed Detail (Height and Width) | 0.020 | 0.50 |

| Minimum Engraved Detail (Height and Width) | 0.020 | 0.50 |

| Clearance | 0.020 | 0.50 |

| All Rubber (TPE) Increased Minimum Parameters (Above) | 0.050 | 1.30 |

*Build volume is up to 27.6 x 15 x 22.9 inches. Larger models can be made in sections and pieced together after printing.

**Large SLS parts can be prone to warp, which explains the scaling tolerance. Minimum tolerances are +/- 0.010.

Standard Material Properties

This data is provided for the convenience of our customers. It does not on its own represent a sufficient basis for any part design, nor does it provide any agreement about or guarantee the specific properties of a product or part or the suitability of a product or part for a specific application. It is the

responsibility of the producer or customer of a part to check its properties as well as its suitability for a particular purpose. This also applies to any possible intellectual property rights as well as regional laws and regulations. The data are subject to change without notice.

For a complete list of data sheets for our nylon product offerings, please click the material links below.