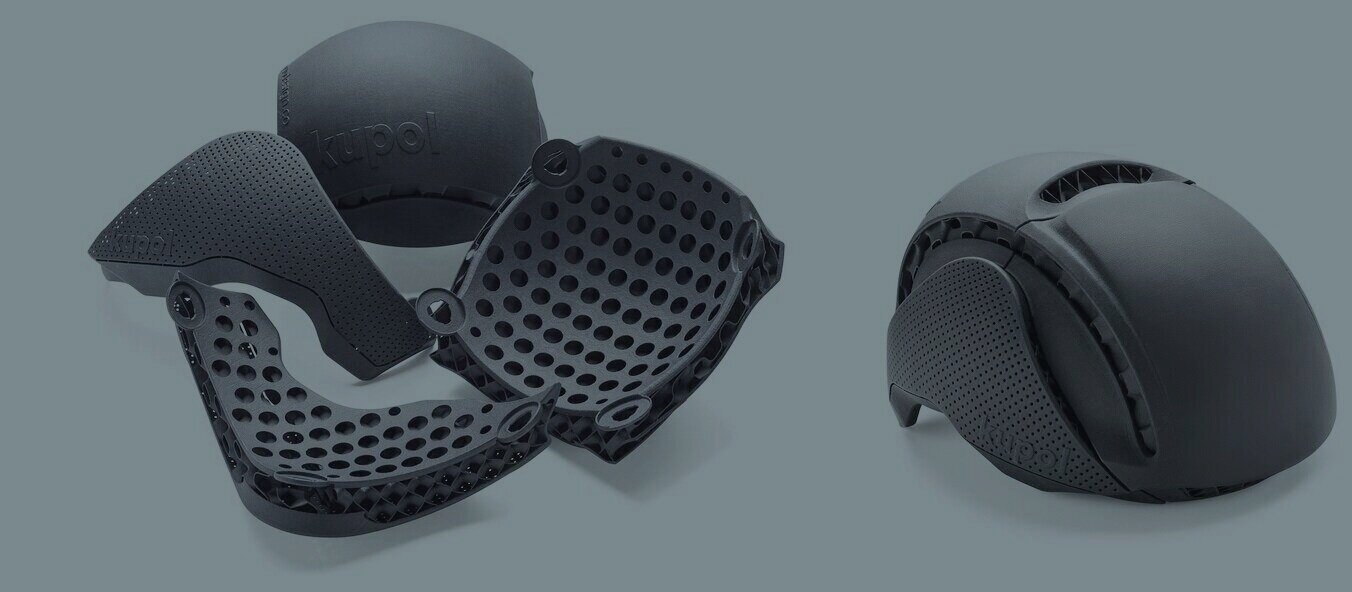

Painless. Cost-Effective. Quicker Production.

Meet growing demands with 3D Printing Technology

Compared with injection molding, 3D printing produces industrial-strength, high-quality parts – without the need for time-consuming, expensive molds. In addition to being costly and delicate, tooling for injection molding requires months of production and consumes upwards of tens of thousands of business dollars.

Unlike physical inventory, digital files give you the bandwidth to implement fast and effortless design changes – meaning you don’t have to pay to produce a revamped design like you would with injection molding. Plus, design modifications and tweaks can be made instantly.

There are no additional setup costs associated with 3D printing, and you can receive parts in as little as two days.

Whether you’re looking to create industrial-strength parts, functional prototypes, or final products, RapidMade uses innovative technology

and materials to furnish our clients with optimal results, faster turnaround times,

and cost-savings. Have Questions? We’d love to hear from you. Contact us directly!

Cutting Edge 3D Printing Services

At RapidMade, we provide the most advanced industrial 3D printers and materials available on the market. Among many others, we offer direct metal printing, HP Multi Jet Fusion, ColorJet, and more.

Want to delve deeper into the world of 3D printing? Check out our Complete Guide to 3D Printing, which outlines everything you need to know about the technology behind 3D printing, design principles, and supply chains.

Below please find the full list of 3D printers and 3D printed materials we provide:

“Our company has procured industrial 3D printed parts through RapidMade for nearly 5 years now. We've been very happy with the service, quality, and price of parts using SLS and MJF processes; in addition, RapidMade sales engineers have been very helpful in recommending design tweaks to improve product outcomes.

“We've deployed these products in California, Colorado, Kenya, Rwanda and Ethiopia. Even now that we are no longer based in Portland, we still do our industrial 3D printing through RapidMade.”

— Taylor Sharpe, SweetSense Inc.