Fused Deposition Modeling (FDM)

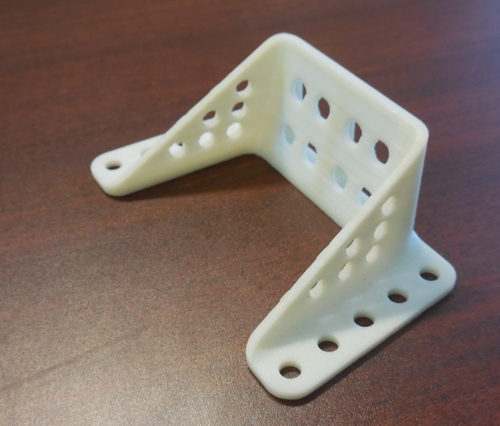

Fused deposition modeling, also known as fused filament fabrication, creates 3D printed plastic parts by extruding thermoplastic filaments in successive layers. FDM 3D printing provides high dimensional accuracy and consistency on every part. Because of the strength and durability of industrial thermoplastics like ABS, PC and Ultem, it is ideal for fixtures, stamping tools, mechanical prototypes, form-fit-function models and small-batch production.

3D printed plastics are durable, inexpensive and quick to produce. They also eliminate many of the design restrictions of traditional manufacturing. To learn more about our other 3D printed plastic options, check out our HP Multi Jet Fusion 3D printing services or our 5-Minute Buyer’s Guide.

FDM 3D Printing, On Demand

Get a quote that works for you with our Instant Quote and Classic Quote tools. Instantly quote and order 3D printed parts for Multi Jet Fusion, FDM, PolyJet, ColorJet and Direct Metal with Instant Quote, or use Classic Quote to get a quote in under 24 hours for all of our manufacturing and engineering services!

FDM Design Guidelines

When using the data below, please keep in mind that FDM materials are orthotropic, not isotropic. As a result, FDM materials have different material properties for different directions.

Please note that these are are guidelines, not hard-and-fast rules. Follow these, and you should be in pretty good shape. We'll let you know if we see any problems with your design.

| Parameter | Inches | Millimeters |

| Maximum Part Size | 36 x 24 x 36* | 914 x 609 x 914* |

| Expected Tolerance | +/- 0.2%** | +/- 0.2%** |

| Minimum Supported Wall Thickness | 0.040 | 1.00 |

| Minimum Unsupported Wall Thickness | 0.020 | 0.50 |

| Minimum Supported Bosses | 0.040 | 1.00 |

| Minimum Unsupported Bosses | 0.020 | 0.50 |

| Minimum Embossed Detail (Height and Width) | 0.040 | 1.00 |

| Minimum Engraved Detail (Height and Width) | 0.040 | 1.00 |

| Clearance Between Parts/Bodies | 0.020 | 0.50 |

*Build volume is up to 36 x 24 x 36 inches. Larger models can be manufactured in sections and assembled after printing.

**FDM allows for some of the highest 3DP tolerances for large parts due to geometric stability. Minimum tolerance is +/- 0.005 in.

Standard Materials

This data is provided for the convenience of our customers. It does not on its own represent a sufficient basis for any part design, nor does it provide any agreement about or guarantee the specific properties of a product or part or the suitability of a product or part for a specific application. It is the

responsibility of the producer or customer of a part to check its properties as well as its suitability for a particular purpose. This also applies to any possible intellectual property rights as well as regional laws and regulations. The data are subject to change without notice.