RapidMade’s Five-Minute Buyer’s Guide

Everything you need to get started with our 3D printing and traditional manufacturing services.

We created this guide to help you determine the best technology and material for your project. It covers every step for developing your custom manufacturing solution with RapidMade, including:

Want to learn more about 3D printing? Check out our Complete Guide to 3D Printing for everything you need to know. You can also learn more about our 3D Printing Services and how we can help on your next project!

Choosing a Manufacturing Technology

RapidMade offers a range of plastic and metal manufacturing services to ensure that we always use the best technology for your project. You can learn more about any option by clicking on it. For full specs on all of our materials, check out our Materials Guide.

Plastic Manufacturing Services

HP Multi Jet Fusion Printing

The fastest, most cost effective plastic printing solution on the market. Superior mechanical strength, finish and fine detail. The best option for most 3D printed plastic projects.

Relative Cost: ★☆☆☆☆

Typical Lead Time: 1-5 business days

Available Materials: Nylon PA-12 (Read more)

Thermoforming

Inexpensive and highly customizable option for creating trays, packaging and more. Uses durable thermoplastics with excellent thermal and mechanical properties.

Relative Cost: ★☆☆☆☆

Typical Lead Time: 2-4 weeks

Available Materials: ABS, PETG, Styrene and many more (Read more)

Fused Deposition Modeling (FDM)

Quick and durable 3D printed plastic parts. Compatible with a variety of materials. Very accurate for large plastic products. Less suited for fine details.

Relative Cost: ★★☆☆☆

Typical Lead Time: 2-7 business days

Available Materials: ABS, PC, nylon, ULTEM and many more (Read more)

Plastic Machining

High-quality surface finish and unmatched accuracy, especially for fine details. Well suited for small- to medium-sized production runs, including rapid prototyping. Generally more expensive than 3D printing.

Relative Cost: Quantity and lead dependent

Typical Lead Time: 2-4 weeks

Available Materials: ABS, HDPE, acetal, nylon, custom materials available on request (Read more)

Selective Laser Sintering (SLS)

Excellent thermal and mechanical properties. Printed plastics can be hard, tough, or flexible as needed. Very cost effective at high volumes. Large, thick parts can warp.

Relative Cost: ★★★☆☆

Typical Lead Time: 5-10 business days

Available Materials: Nylon-, carbon- and glass-filled nylon, rubber (TPU) and other composites (Read more)

Silicone & Urethane Casting

A faster, less expensive alternative to injection molding for small- to medium-sized runs with lower tooling costs and shorter lead times. Produces high-quality parts with detailed textures and consumer-quality finishes.

Relative Cost: ★★★☆☆

Typical Lead Time: 5-12 business days

Available Materials: Rigid and rubber urethane, acrylic, silicon, resins, plaster, composites and other custom materials (Read more)

ColorJet Full-Color Composite

The best way to produce full-color 3D printed plastic models with a full gradient of 339,000 colors. Very fast and inexpensive. Works best for medium to large products, as details smaller than 0.100” can be brittle.

Relative Cost: ★☆☆☆☆

Typical Lead Time: 2-5 business days

Available Materials: Full color composite (Read more)

Injection Molding

The tried-and-true method for high-volume manufacturing with the best quality and lowest cost. Longer lead times and higher tooling costs than 3D printing mean injection molding is generally not suited for smaller orders.

Relative Cost: Quantity and time dependent

Typical Lead Time: 4-12 weeks

Available Materials: ABS, polycarbonate, polypropylene, polyethylene, nylon, TPU and other custom materials (Read more)

PolyJet (Objet) Printing

Excellent surface finish, complex textures and fine details. Resins available in rubbery or rigid textures. Less appropriate for large plastic parts due to lower heat resistance.

Relative Cost: ★★★☆☆

Typical Lead Time: 2-7 business days

Available Materials: Acrylic and polypropylene-like, ABS-like, various elastomers and digital materials (Read more)

Large Format 3D Printing

The best (and sometimes only) option for very large printed plastic parts. Great alternative to traditional machining for casting patterns and molds. Less durable than SLS or FDM.

Relative Cost: ★★★☆☆

Typical Lead Time: 5-10 business days

Available Materials: Epoxy-infused acrylic, sand (sand casting), low-ash burnout resin (investment casting) (Read more)

Metal Manufacturing Services

Direct Metal Printing

The best choice for small- to medium-sized production runs of metal parts. The most economical metal 3D printing. Far less expensive than DMLS at appropriate quantities. Best for parts smaller than 5”.

Relative Cost: ★★★☆☆

Typical Lead Time: 1-3 weeks

Available Materials: Stainless steel, stainless steel/bronze alloy, tungsten-bronze (Read more)

Metal Machining

The most accurate metal manufacturing, with the widest range of materials, tightest tolerances and best surface finish. Good option for small runs or metal tooling.

Relative Cost: Quantity and lead dependent

Typical Lead Time: 2-4 weeks

Available Materials: Aluminum, stainless steel, custom materials available on request (Read more)

Direct Metal Laser Sintering (DMLS)

Useful for complex designs or exotic metals that would be prohibitively expensive to produce with traditional machining. Designs generally cannot be larger than 10”.

Relative Cost: ★★★★★

Typical Lead Time: 5-15 business days

Available Materials: Aluminum, stainless steel, tool steel, titanium, cobalt chrome, inconel (nickel alloy) and more (Read more)

Printed Metal

Substantially less expensive than DMLS, but only compatible with stainless steel bronze alloy. Lower strength to weight ratio than other metals. Longer lead time relative to other 3D technologies.

Relative Cost: ★★★★☆

Typical Lead Time: 10-20 business days

Available Materials: Stainless steel bronze alloy (Read more)

Finishing Options

Our custom finishing services allow you to further improve the aesthetics, durability and branding of your products. Click any finish to get more information, including price and materials details.

Dyed Plastic Finish

Standard dyes include include black, red, blue, green, purple and orange, with custom dyes available on request. Opaque dyes are available for PolyJet and FDM. PolyJet also supports translucent dyes. Multi Jet Fusion and SLS both have opaque black options.

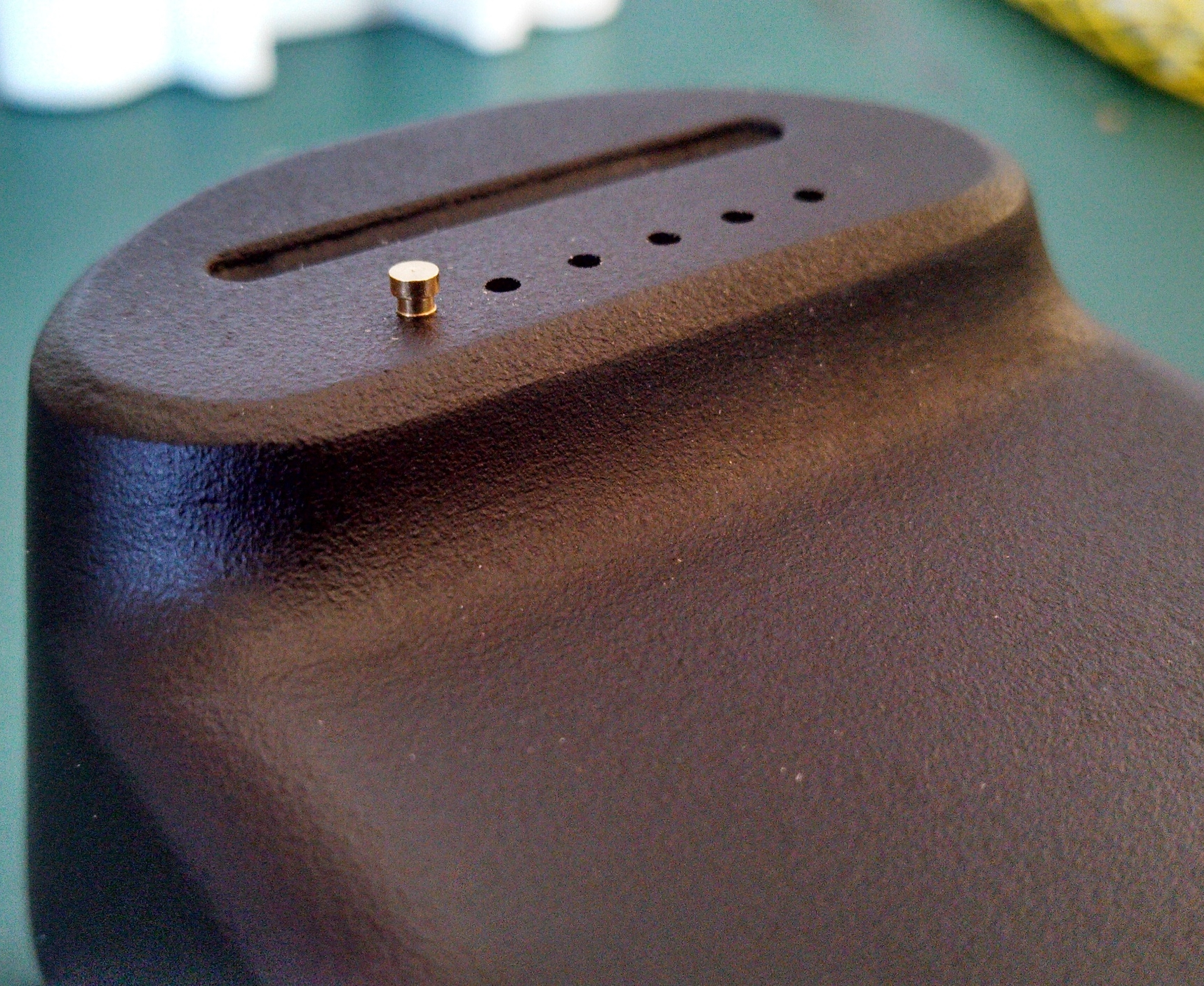

Sanding, Blasting, Tumbling and Clear Coating

These standard finishes are available on almost all RapidMade products. They provide smoother textures and higher quality, consumer-grade feel. We are also able to simulate wood texture on ColorJet parts.

Custom Painted Finish

We can create clear topcoats as well as single- and multi-color custom paint finishes on almost all RapidMade products. Paints are available in matte, satin and gloss.

Custom Coatings

Available on most of our products, custom coatings like Teflon, Cerakote and polyurethane improve abrasion resistance, enhance appearance and reduce friction.

Metal Polishing

Polishing improves resistance to abrasion and makes parts easier to clean and sterilize. It also amplifies the appearance of secondary finishes like anodizing, silk screen, plating and powder coating.

Plastic and Metal Plating

Great for surface conductivity and electromagnetic interference applications, plating adds strength and rigidity to plastic parts while providing an elegant, metal-like appearance. It further improves the appearance of metal products.

Powder Coating

Powder coating is an inexpensive, permanent finish which protects metals from scratches, rust and corrosion while hiding imperfections. It has a smaller environmental impact than other coating processes.

Anodizing

Anodizing prevents corrosion on aluminum components, creates a harder surface that is more resistant to wear and comes in many color options.

Laser Engraving

Less expensive than CNC engraving, laser engraving is simple to create. It can be done directly from a PDF and allows for custom branding or engraving part and serial numbers.

Sending Us CAD Files

CAD files are the best way to send us your design. This list shows our favorite file types in order of preference. If your file type does not appear below, we can probably still work with it. If you do not have a CAD file, you may be interested in our product design and engineering services.

Engineering and Design

STEP (.STP, .STEP)

IGES (.IGS, .IGES)

Parasolid (.X_B, .X_T)

AutoCAD (.DXF, .DWG - 3D, not 2D)

SolidWorks (.SLDPRT, .SLDASM, .SLDDRW)

Inventor (.IPT, .IAM)

Standard 3D Printing

Stereolithography (.STL)

Wavefront (.OBJ)

Polygon File Format (.PLY)

AutoCAD (3D .DXF, 3D .DWG)

Rhino (.3DM)

Color 3D Printing

ZCorp (.ZPR)

Wavefront (.OBJ—must include MTL file and texture maps)

Filmbox (.FBX)

Autodesk (.3DS)

Polygon File Format (.PLY)

Rhino (.3DM)

Virtual Reality Modeling Language (.WRL)

Custom Quotes, Fast

Get a quote that works for you with our Instant Quote and Classic Quote tools. Instantly quote and order 3D printed parts for Multi Jet Fusion, FDM, PolyJet, ColorJet and Direct Metal with Instant Quote, or use Classic Quote to get a quote in under 24 hours for all of our manufacturing and engineering services!

Still have questions?

Check out our 3D Printing FAQ or reach out to us directly. A RapidMade representative will be happy to answer any questions you may have.