When we talk about 3D printing, it is a catch-all phrase that encompasses several distinct technologies, each with its own strengths. Here are some comparisons of additive manufacturing options in plastic, metal and composites:

3D Printed Plastics

Fused Deposition Modeling (FDM)

Learn more about FDM

Standard Materials: ABS

Relative Cost: ★★☆☆☆

Machine Finish: ★★☆☆☆

ABS Prime Finish: ★★★★★

Typical Lead Time: 2-5 Business Days

Specialty Materials: PC, nylon, ULTEM and many more (See FDM page)

Relative Cost: ★★★★☆

Machine Finish: ★★☆☆☆

Typical Lead Time: 3-7 Business Days

FDM Pros: Very high accuracy on large parts, diverse materials, rigid and tough, fast turnaround, sparse fill for light weight with high part volumes

FDM Cons: Striated machine finish, low resolution on features under 0.030"

Polyjet (Objet) Printing

Standard Materials: Acrylic and polypropylene-like

Relative Cost: ★★★☆☆

Machine Finish: ★★★★★

Typical Lead Time: 2-5 Business Days

Specialty Materials: ABS-like, various elastomers and digital materials (See Polyjet Page)

Relative Cost: ★★★★☆

Machine Finish: ★★★★★

Typical Lead Time: 3-7 Business Days

Polyjet Pros: Top quality detail, best surface finish, clear material option, embedded textures, fine features, single piece mechanical assemblies

Polyjet Cons: Resins - not industrial thermoplastics, lower heat resistance, better for smaller parts

Selective Laser SIntering (SLS)

Standard Materials: Nylon and glass filled nylon

Relative Cost*: ★★★☆☆

Machine Finish: ★★★☆☆

Typical Lead Time: 5-10 Business Days

Specialty Materials: Rubber (TPU), carbon filled nylon and other composites (See SLS page)

Relative Cost: ★★★★☆

Machine Finish: ★★★☆☆

Typical Lead Time: 5-10 Business Days

SLS Pros: Real thermoplastic and thermoplastic composites, uniform matte finish, great thermal and mechanical properties

SLS Cons: Large and thick parts can warp, longer production lead times, porous material, low resolution on features under 0.030"

*In volume SLS can become one of the least expensive printing processes.

Large Format 3D Printing

Learn More about Large Format 3D Printing

Standard Materials: Epoxy infused Acrylic

Relative Cost*: ★★★☆☆

Machine Finish: ★★★☆☆

Typical Lead Time: 5-10 Business Days

Specialty Materials: Sand (Sand Casting), Low Ash Burnout Resin (Investment Casting)

Relative Cost: ★★★☆☆

Machine Finish: ★★★☆☆

Typical Lead Time: 5-10 Business Days

Large Format Pros: Largest build size of any 3D printers, cost effective for large parts, casting patterns and molds without any additional tooling

Large Format Cons: Not as durable as SLS or FDM, not intended for small objects, longer production lead times compared to smaller printers

3D Printed Metals

Note: 3D printed metals tend to be 5 to 10 times the cost of 3D printed plastics and are often more expensive than machined metals.

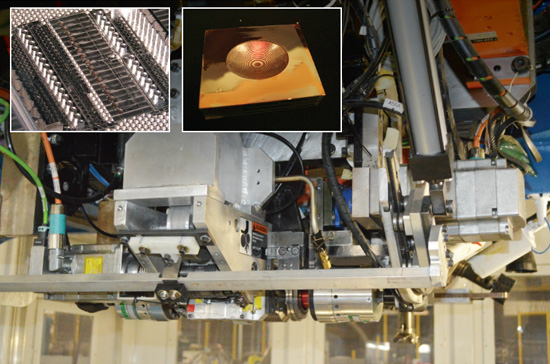

Direct Metal Laser Sintering (DMLS)

Standard Materials: Aluminum, stainless steel, tool steel and titanium

Relative Cost: ★★★★★

Machine Finish: ★★☆☆☆

Typical Lead Time: 5-15 Business Days

Specialty Materials: Cobalt chrome, inconel, (nickel alloy) and more (See DMLS page)

Relative Cost: ★★★★★

Machine Finish: ★★★☆☆

Typical Lead Time: 5-15 Business Days

DMLS Pros: Stronger than cast parts, works with exotic and expensive to machine metals, can make parts that are otherwise not manufacturable

DMLS Cons: Limited part size (generally under 10"), rough finish, lower tolerance than machining, generally more expensive than machining

Printed Metal

Learn more about Printed Metal

Standard Materials: Stainless steel bronze alloy

Relative Cost: ★★★★☆

Machine Finish: ★★☆☆☆

Typical Lead Time: 10-20 Business Days

Specialty Materials: None

Relative Cost: N/A

Machine Finish: N/A

Typical Lead Time: N/A

Printed Metal Pros: Half to a third the cost of typical DMLS parts, beautiful bronze polish look, easily plated, larger bed than DMLS

Printed Metal Cons: Single available material, low strength to weight ratio for metal, long lead time relative to other 3D technologies

3D Printed Composites

Colorjet Full Color Composite

Standard Materials: Full color composite

Relative Cost: ★☆☆☆☆

Machine Finish: ★★★☆☆

Typical Lead Time: 2-5 Business Days

Specialty Materials: None

Relative Cost: N/A

Machine Finish: N/A

Typical Lead Time: N/A

Full Color Composite Pros: Full gradient of 390,000 colors, generally least expensive material, fastest way to make large models, very rigid

Full Color Composite Cons: Features thinner than 0.100" can be brittle, does not have the flex of real plastic