Industrial Pattern and Tool Making

Increase Speed-to-Market, Reduce Costs,

and Improve Quality

Explore Available Tooling and Parts We Offer:

Epoxy and Silicone Molds

Numerous casting materials available, including Urethane, epoxy, polyester, medical- and food-grade resins, plaster, and many other resins and composite materials.

Receive tooling within days, not months.

Reduces costs associated with short-run productions.

Reusable tooling ideal for sustainability and producing multiple castings.

Material costs are lower than 3D printing.

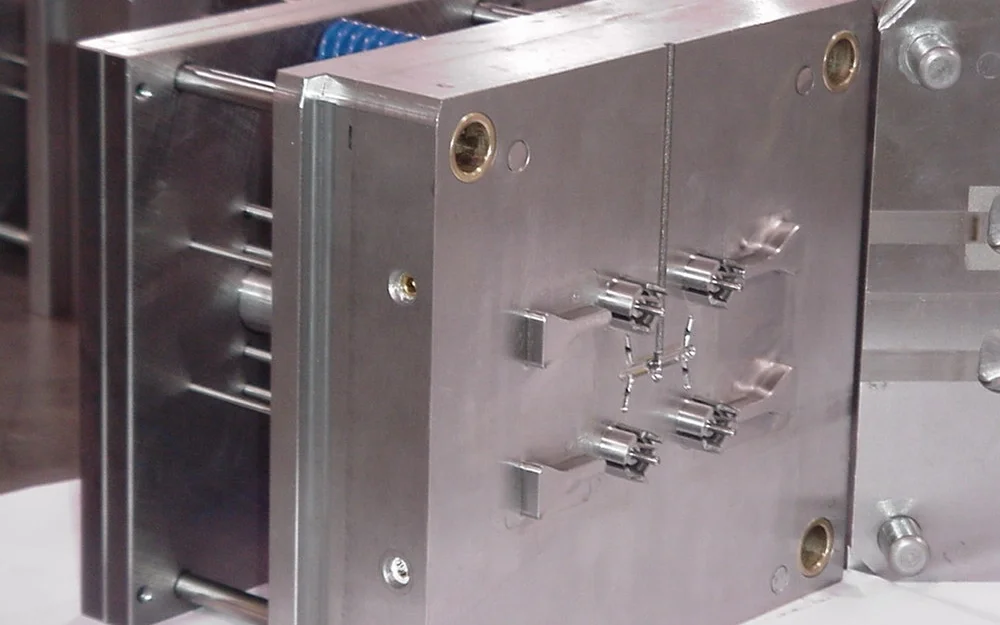

Injection Molds and Inserts

Very inexpensive costs surrounding parts.

Injection mold tooling delivered within days or weeks in lieu of months.

Very inexpensive costs surrounding parts.

Top-quality aesthetic finish and mechanical properties compared to other rapid prototype technologies.

Long tool life: over ten thousand units for prototype tooling, hundreds of thousands of units for production tooling.

Sand Casting Patterns

The least expensive way to fabricate small quantities of small to large metal parts.

Tooling can be produced in less than 1-2 weeks at a fraction of the price of traditional methods.

Typical materials used include aluminum, bronze, zinc and steel.

Capable suppliers of core boxes, follow boards, gates and risers and other necessary sand cast tooling.

Investment Cast Patterns, Molds and Waxes

Produces the highest quality finish of all casting methods available.

Typical materials include aluminum, bronze and steel.

Able to print one-off or small batches of direct burnout patterns without investing in wax tooling.

Available tooling includes master patterns, silicone rubber molds and wax burnout patterns.

Vacuum and Thermoform Tooling

Prototype tooling available in as little as 2 days.

Production tooling is good for over 100,000 forms and is porous for superior part quality.

Able to construct parts up to 12 feet in length.

Heavy gauge production plastics available, such as ABS, Polyethylene, Polystyrene and Polycarbonate.

Light gauge packaging plastics like PET and Polystyrene are available.

Carbon Fiber, Fiberglass and Other Composite Tools

Reduced tooling and mold lead time compared with traditional methods.

Increase complexity of design without inflating cost.

Cost-savings on both prototype and production tools.

Waxed finishes available for easy de-molding.

Soluble cores are available for hollow parts.

Sheet Metal Stamping and Forming Tools

Minimal cost tooling for small batches of sheet metal parts.

Tools delivered in a fraction of the time compared to traditional methods.

Male and female tooling available for traditional two-die stamping as well as single-die hydro-forming.

Inexpensive and durable composite tooling available as castings from patterns.

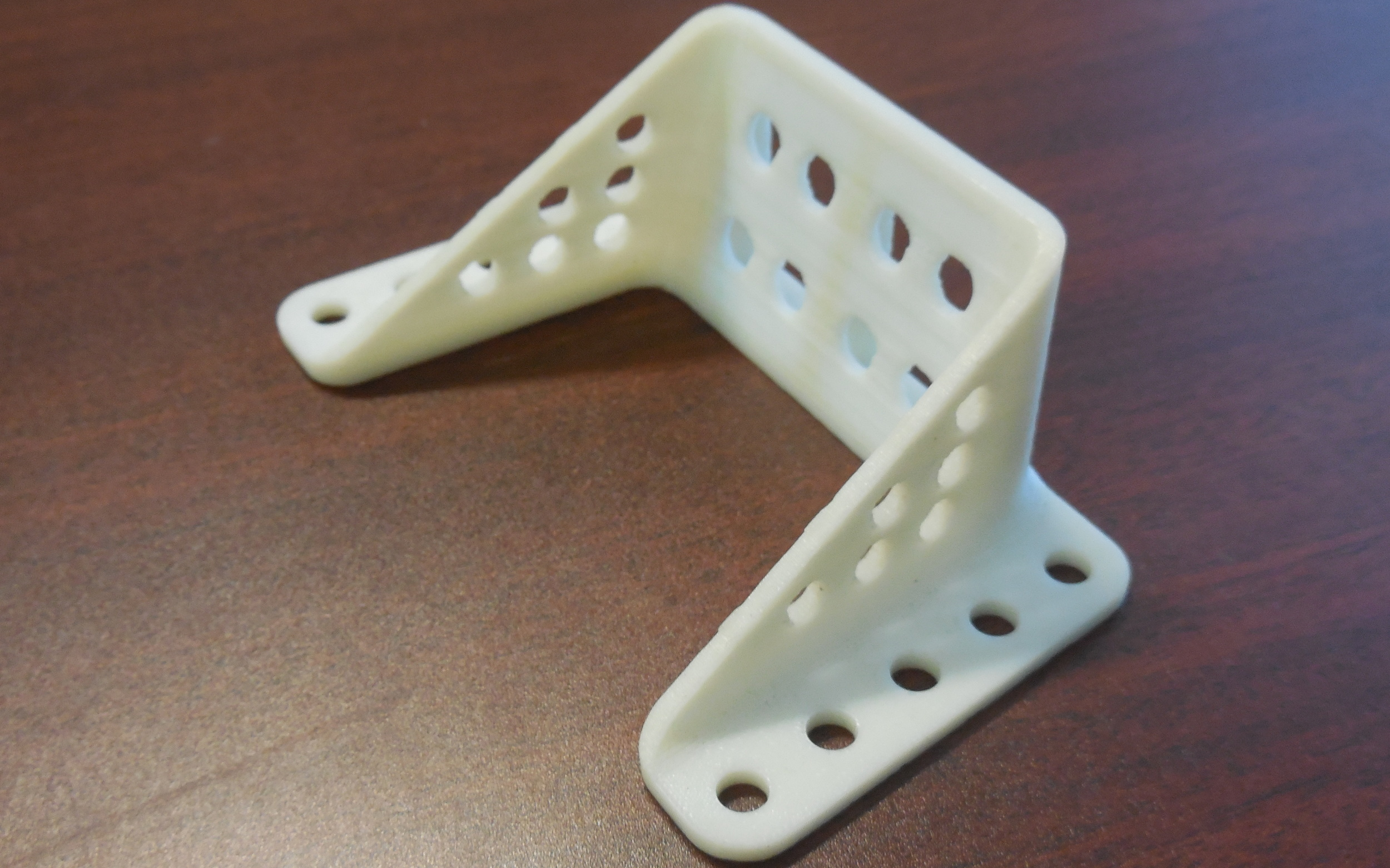

Robotic Arm End Effectors

Custom tooling that fits any part with complex internal geometries like vacuum channels.

Simplified designs are easier to engineer, manufacture and assemble, cutting down on cost and time for tooling fabrication.

Reduce weight, inertia and material waste during fabrication.

Improve tool life by cutting down on breakable components.

Molded Paper Pulp Packaging Tools

Get high-accuracy tooling for a fraction of the cost of machined tools.

Prototype tooling can also be used as permanent tooling for thousands or even tens of thousands of molds.

Tools can be used as patterns to make tooling for multiple lines or facilities.

Tools can be turned around in days instead of weeks.

Custom Jigs, Clamps, Fixtures and Other Tooling

Most miscellaneous tooling can be fabricated rapidly at a lower cost using additive manufacturing.

Quickly test for geometric conformity or hold parts for post operations or inspection.

Able to use existing CAD data for the part to design mating tooling.